Private Label Sunglasses And Eyewear Process

Private label sunglasses and eyewear are products that are production by sunglasses manufacture, but sold with your brand logo.

If you are interested in private labeling sunglasses and eyewear for your company, you may want to consider working with a sunglasses manufacturer that specializes in this type of product. They will have the experience and expertise to help you create a product that meets your specific needs and requirements.

Table of Contents

1. Introduction

Private Label Sunglasses: A Blend of Style and Function

Sunglasses, both stylish and useful, have been loved since the Roman Empire. They protect our eyes from UV rays and add to our style. The growing need for cool and high-quality glasses makes the private label sunglasses market a good chance for people to start your own brands.

- A Comprehensive Guide to Building a Successful Private Label Sunglasses Brand

This full guide talks about private label sunglasses and how to make a successful eyewear brand. We’ll cover knowing the glasses market, who to sell to, brand image, and finding the right maker, and how to work with glasses makers, giving you tools and tips to start your sunglasses business. By the end, you’ll be set to join the private label glasses world.

2. The Private Label Sunglasses Business Model and Its Advantages

Private label sunglasses are made in eyewear manufacturer, and you focused sold them.This lets you focused work on design, ads, and sales while letting manufacturer making the glasses.

Private labeling eyeglass is getting more popular in the glasses world, as it’s a cheaper and faster way for people to create special, high-quality products and sell them just under your own brand.

The private label business model gives some good things to people who start businesses, like:

- Lower start-up costs

Working with iDetail Eyewear Manufacturer means you don’t need to spend on making equipment, places, and trained workers, and can use bigger production to lower sunglass costs. This cuts down starting costs and makes it easier for entrepreneurs to join the market.

- Quicker market entry

By partnering with an experienced iDetail, you can tap into their expertise to optimize the product development and manufacturing process, leading to a faster market entry.

- Customization

Private label eyewear offers for a high level of customization, letting brands make unique products for their audience’s likes and needs.

Increased control over product design and quality

Eye glasses Quality is a top priority. Making a product that matches your brand idea and high quality is key. Working with a good glasses manufacturer makes sure products use high-quality materials and follow strict quality standard.- Higher profit margins

With lower production costs and the ability to set your own retail prices, you can achieve higher profit margins than if you were selling a branded product.

- Scalability

As your sunglasses brand grows, you can easily expand your product line, and increase production capacity by working with your iDetail manufacturing partner.

- Brand recognition

By creating a unique and memorable brand, you can build customer loyalty and foster long-term relationships with your target audience.

3. Understanding the Private Label Sunglasses Market and Target Audience

Checking competitors and finding opportunities in the market is important too. Some main points are:

- The Global Sunglasses Market

The market around the world is doing well and has a lot of competition, worth billions of dollars. It will likely keep growing in the future because people care more about protecting their eyes, outdoor activities are getting popular, and fashion trends have a big impact.

- Key Industry Players

The market has some big companies like Luxottica Group, Safilo Group, Essilor, and Marcolin Group. They succeed by offering many products for different customers. Also has some smaller brands and private label sunglasses for special markets and needs.

These brands are and will stay popular, being part of many people’s collections, including Dutz, Vuarnet, Anne et Valentin, Garrett Leight, Matthew, Vistan Brillen, Francis Klein.

- Market Trends and High Standard For Quality

The sunglasses business is greatly affected by fashion trends, which decide the popular styles, colors, and materials people like. Some trends are changing the sunglasses market when it comes to quality.

These trends change what customers want and how they buy, affecting the materials, technologies, and designs used to make sunglasses. key trends in the last few years include:

A. Target Audience :

Find out the different groups in the market and choose the one that fits best with your brand’s ideas. Figure out who you want to sell to, like age, gender, income, and what they like to do, and make your products match what they want.

(1)Fashion-conscious consumers

People who care about style see sunglasses as a fashion accessory, looking for the newest trends and famous brands. They’re ready to pay more for top-quality, fashionable sunglasses that stand out and go well with their outfits. Social media stars, famous people, and fashion magazines drive this part of the market.

(2)People who love the outdoors

People who enjoy outdoor activities like hiking, biking, and water sports need sunglasses that give the best eye protection and work well. They care about things like UV protection, polarized lenses, and strong materials. Brands for this group often make sunglasses specially designed for different outdoor activities and places.

(3)Value-driven shoppers

For budget-focused buyers, cost and usefulness matter most when buying sunglasses. This group cares a lot about price and wants cheaper choices that still protect their eyes and look good. Brands for these customers usually make low-cost sunglasses that have a nice balance between quality and price.

(4)Health-focused consumers

They care about eye protection and often buy sunglasses with better lens technology, like polarized or photochromic lenses. They follow healthcare experts’ advice and choose sunglasses that protect their eyes from harmful UV light and other things outside.

(5)Conclusion

Understanding the sunglasses market and the target customers is important for businesses to succeed in this competitive area. By noticing trends, major brands, and customer needs, companies can create better, good-looking products that people want. By keeping up with the changing market, businesses can adapt to customer preferences and stay ahead of competitors.

B. In terms of quality :

Paying attention to materials and how well things are made, many needs and trends are showing up in the sunglasses market, because customers care more about quality and lasting a long time.

These trends change what people want and how they buy, affecting the materials, technologies, and designs used to make sunglasses.

- Want for high-quality lenses: Many people now want sunglasses with high-quality lenses to protect their eyes from bad UV rays and see clearly. Polarized lenses, photochromic lenses, and lenses with special coatings (like anti-glare, anti-scratch, and water-resistant) are getting popular because they improve vision comfort and last longer.

- Focus on materials and craftsmanship: Focus on materials and quality: Sunglasses made from top-quality materials, like acetate, titanium, and stainless steel, are in demand because they’re durable, lightweight, and comfortable. Brands making handcrafted frames and paying attention to details are also popular because people appreciate the added value of well-crafted items.

- Sustainable and eco-friendly materials: People are becoming more aware of the environment, so there’s more demand for earth-friendly materials. Brands using recycled plastics, bio-based materials, and responsibly gathered wood for frames are getting popular with customers who care about the environment.

- Performance eyewear: More people want sunglasses for specific activities like sports, outdoor fun, and water sports. These sunglasses have special lenses, like mirrored or colored ones, and comfy, secure frames for intense activities.

- Fashion and functionality: People want sunglasses that are stylish and useful. This has brought new designs like foldable frames, swappable lenses, and custom features. Glasses that look good and have helpful features, like blue light blocking, are also becoming popular.

- Smart sunglasses: With new tech, smart sunglasses with things like Bluetooth speakers, bone conduction sound, or augmented reality are appearing. Even though they’re still a special group, these high-quality, tech-packed sunglasses offer more worth and help to those who like wearable devices.

In short, the sunglasses market wants better quality items with improved use, how long they last, and fashion. People like sunglasses that guard their eyes, use the best materials, and have new tech, making quality key.

Companies that can follow these trends and match changing customer wants will likely succeed in the tough sunglasses market.

4. Developing Your Private Label Sunglasses Brand Identity and Design

Building a strong brand image is important for your private label sunglasses business to succeed.

Your brand should match your audience’s likes and be different from competitors. Main parts of your brand identity are:

- Create a brand mission and vision

Make a clear mission statement explaining your sunglasses brand’s story and main goal. Write a vision statement about your brand’s long-term hopes and connect with your target customers. In short, a strong brand story can guide you and help you reach your dreams more easily.

Design your brand’s visual identity:

- Develop a color palette that reflects your brand personality and appeals to your target audience.

- Choose typography and fonts or patterns that complement your brand’s style and are easily readable.

- Design a logo that is unique, memorable, and scalable for various applications.

- Make more visual parts (like patterns, symbols, drawings) that can be used the same way in marketing stuff and products.

- Establish a brand style guide

Make a detailed brand style guide with your brand’s visual and verbal elements. Include rules for your logo, fonts, colors, pictures, and speaking style. Make sure your guide is easy for everyone on your team and partners to use when making content, ads, or products.

- Design your own sunglasses collection

Create sunglasses designs that match your brand and what your audience likes. Think about things like frame shapes, materials, colors, lens tech, and useful features. Work with designers, makers, or product teams to make sure your designs follow your brand’s standards and vision.

- Develop packaging and marketing materials

Design packaging that show your brand and adds value to the customer experience.Create ads like catalogs, books, or promo items to show your sunglasses and brand story. Make sure all packaging and ads follow your brand guide and have the same design and message.

5. Finding a Reliable Sunglasses Manufacturer

Once you’ve developed your eyeglass frames brand identity and design, it’s time to find a reliable manufacturer to produce your custom private label sunglasses. Some factors to consider when choosing a manufacturer include:

5.1 Distribution of manufacturers

Eyewear manufacturers are mainly concentrated in Italy, primarily in the Belluno eyewear industrial zone located in the Veneto region of northern Italy, which produces 80% of the country’s eyewear output. The eyewear products are mainly focused on producing sunglasses and frames.

In China, around 73% of the world’s eyewear is produced, mainly concentrated in Shenzhen and Dongguan (for mid-high-end eyewear), Danyang and Wenzhou (for mid-low-end eyewear), and Xiamen (for mid-range brand sunglasses).

In Japan, there is a focus on handmade eyeglass frames and titanium eyeglass frames, while in Germany, the main focus is on stainless steel and titanium eyeglass frames.In South Korea, the main production area is for plastic steel, also known as tungsten carbon TR90 frames.

Overall, China has the most complete industry chain and resources, with relatively lower costs.

5.2 Some ways to find eyewear manufacturers

- Search Engines: Use search engines like Google, bing, youtube, etc. to search for related keywords such as eyewear manufacturers or eyeglass factories. This can help you find many eyewear manufacturers’ official websites or related information.

- Exhibition: The main exhibitions are MIDO , SILMO , Opti, Vision Expo East , HongKong Optical Fair ; Participating in eyewear trade shows can directly contact eyewear manufacturers to learn about product information, prices, and other relevant information.

- Agents: Some agents or wholesalers can provide information about eyewear manufacturers, and can also provide more help, such as price negotiation, logistics, etc.

5.3 Must-have conditions for eyewear manufacturers:

- Experience and expertise: A reliable glasses manufacturer should have a proven track record in producing high-quality glasses and a strong understanding of the eyewear industry. They should be knowledgeable about various materials, lens technologies, and production processes.

- Relevant certifications: The manufacturer should hold relevant certifications that demonstrate their commitment to quality and adherence to industry standards. These may include ISO (International Organization for Standardization) certifications, CE (Conformité Européene) marking, or FDA (U.S. Food and Drug Administration) approval.

- Quality control: A reliable manufacturer should have a robust quality control system in place to ensure the consistent production of high-quality glasses. This may involve regular inspections, testing, and monitoring throughout the production process.

- Production capacity: The manufacturer should have the capacity to meet your production requirements, including the ability to scale up production as your business grows. They should also be able to handle the complexities of producing different styles and designs while maintaining consistent quality.

- Clear talking: Being open and clear when talking is needed for a good partnership with a glasses maker. They should quickly answer your questions, give updates on how making is going, and be ready to fix any problems or worries that come up.

- Competitive pricing: While it’s essential to prioritize quality, a reliable glasses manufacturer should also offer competitive pricing that aligns with your budget and business goals.

- Payment Terms: When working with eyewear manufacturers, it’s essential to negotiate payment terms that balance the needs and risks of both parties. Always ensure that the terms are clearly outlined in the contract or purchase agreement to avoid misunderstandings or disputes.

- Fair and green actions: A good Eyewear Manufacturer should follow fair work rules and care about worker safety and happiness, and respect and protection of intellectual property. Also, they should try to use eco-friendly ways to make glasses and materials when they can.

- Flexibility and adaptability: A reliable glasses manufacturer should be able to adapt to your changing needs and requirements, whether it’s modifying designs, incorporating new materials, or adjusting production quantities.

- Positive reputation: Finally, a good maker should be well-known in the business, with happy customers and past successful work. Ask people in the industry or look online to find makers with a strong name.

By considering these features helps you find a good glasses maker who fits your needs and makes high-quality glasses for your business.

Keep in mind that having a strong partnership with your maker needs clear talking, trust, and both sides caring about quality and making customers happy.

6. Private Label Sunglasses Process With Eyewear Manufacturers

Each pair of glasses shares a story with many parts and people: our brands, creative groups, researchers, and sample, making, and growing departments.

All the collections made by iDetail Eyewear maker go through a tough technical and quality checking process to give eyeglass frames with a one-of-a-kind design and a great fit, while keeping the best quality standards.

(1)Working together on technical design

Work with the maker’s design and engineering groups to check and improve your sunglasses designs, looking at technical things like stress points, weight balance, and comfort. Find and fix possible structure issues and make needed design changes.

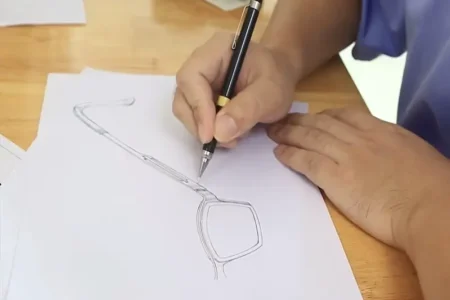

(2)Creation of sunglasses technical drawing and 3D drawings

Work with the manufacturer to make technical and 3D drawings, with exact sizes, material details, and process instructions. This step ensures that all design are shown right and can be made without problems.

(3)Glasses Material selection and testing

Work with the manufacturer to pick the right materials for your sunglasses, thinking about things like how strong, light, comfortable, and expensive they are. Test the materials to make sure they fit your needs and follow industry standards.

(4)Development of sunglasses production process and quality control plan

Work with the manufacturer to set up a clear making process, requirements and notes,Make a quality control plan that explains checking and testing during making to keep the same good quality.

(5)Making and checking prototypes

Ask the manufacturer to make prototypes using the final design, materials, and making steps. Check and make sure they fit your needs and fix any worries or problems.

(6)Customer testing and feedback

Ship the prototypes to customer or testers to check and give their feedback. Learn from their opinions on things like fit, comfort, how they work, and looks to help make possible design improvements.

(7)Design and production adjustments

Using the feedback and checking results, work with the manufacturer to change any needed design or making parts. This might mean changing materials, improving making steps, or fixing quality issues.

(8)Pre-production Color Sample Approval

Once the design and production adjustments are made, request a. pre-production color sample from the manufacturer to ensure all changes have been implemented correctly. Review and approve the sample before moving forward with full-scale production.

(9)Purchase Order confirmation

When brand owner place orders with eyewear manufacturers, they typically include the following items in their order:

- Product details: Exact info on the design, materials, and special parts of the glasses frames. This might have technical drawings, color examples, or other papers to make sure the maker knows the product needs well.

- Quantity: The total number of units to be produced for each model or style, often broken down by size, color, or other differents.

- Quality requirements: Details about the quality standards that need to be followed when making the product, like allowed differences, material goodness, and finishing needs.

- Production timeline: Expected time and exact due dates for each step of the making process, like saying yes to prototypes, color examples, and mass-production.

- Packaging and labeling: Info on the wanted packing and labels for the glasses, like branded stuff, print or laser details, and any needed barcodes or other markers.

- Shipping and logistics: Details on the shipping arrangements, such as delivery dates, shipping methods, and destination addresses for the completed eyewear products.

- Payment terms: Agreement on the payment terms, including the deposit amount, payment schedule, and any applicable penalties or discounts for delayed or expedited production.

- Quality control and inspection: Info on the quality control and checking process, like the procedures to follow, what makes something okay, and if any third-party checking is needed.

- Intellectual property protection: Agreement on the protection of the branded optician’s intellectual property, such as trademarks, design patents, and confidentiality agreements.

By providing this information in your orders, You can ensure that iDetail have a clear understanding of your requirements and expectations, resulting in a smooth and efficient production process..

(10)Mass-production and sunglass quality control

The manufacturer will start mass-production, using the approved making steps, color samples, quality control plan, and order list. They will check and test often during making to keep the same good quality.

(11)Packaging and shipping

Arrange shipping logistics to deliver the finished products to your warehouse or distribution center.

6. Private Label Sunglasses Process With Eyewear Manufacturers

Each pair of glasses shares a story with many parts and people: our brands, creative groups, researchers, and sample, making, and growing departments.

All the collections made by iDetail Eyewear maker go through a tough tech and quality checking process to give glasses with a one-of-a-kind design and a great fit, while keeping the best quality standards.

(1)Working together on technical design

Work with the maker’s design and engineering groups to check and improve your sunglasses designs, looking at technical things like stress points, weight balance, and comfort. Find and fix possible structure issues and make needed design changes.

(2)Creation of technical and 3D drawings

Work with the manufacturer to make technical and 3D drawings, with exact sizes, material details, and process instructions. This step ensures that all design are shown right and can be made without problems.

(3)Glasses Material selection and testing

Work with the manufacturer to pick the right materials for your sunglasses, thinking about things like how strong, light, comfortable, and expensive they are. Test the materials to make sure they fit your needs and follow industry standards.

(4)Development of production process and quality control plan

Work with the manufacturer to set up a clear making process, requirements and notes,Make a quality control plan that explains checking and testing during making to keep the same good quality.

(5)Making and checking prototypes

Ask the manufacturer to make prototypes using the final design, materials, and making steps. Check and make sure they fit your needs and fix any worries or problems.

(6)Customer testing and feedback

Ship the prototypes to customer or testers to check and give their feedback. Learn from their opinions on things like fit, comfort, how they work, and looks to help make possible design improvements.

(7)Design and production adjustments

Using the feedback and checking results, work with the manufacturer to change any needed design or making parts. This might mean changing materials, improving making steps, or fixing quality issues.

(8)Pre-production Color Sample Approval

Once the design and production adjustments are made, request a pre-production color sample from the manufacturer to ensure all changes have been implemented correctly. Review and approve the sample before moving forward with full-scale production.

(9)Purchase Order confirmation

When brand owner place orders with eyewear manufacturers, they typically include the following items in their order:

- Product details: Exact info on the design, materials, and special parts of the glasses frames. This might have technical drawings, color examples, or other papers to make sure the maker knows the product needs well.

- Quantity: The total number of units to be produced for each model or style, often broken down by size, color, or other variations.

- Quality requirements: Details about the quality standards that need to be followed when making the product, like allowed differences, material goodness, and finishing needs.

- Production timeline: Expected time and exact due dates for each step of the making process, like saying yes to prototypes, color examples, and mass-production.

- Packaging and labeling: Info on the wanted packing and labels for the glasses, like branded stuff, print or laser details, and any needed barcodes or other markers.

- Shipping and logistics: Details on the shipping arrangements, such as delivery dates, shipping methods, and destination addresses for the completed eyewear products.

- Payment terms: Agreement on the payment terms, including the deposit amount, payment schedule, and any applicable penalties or discounts for delayed or expedited production.

- Quality control and inspection: Info on the quality control and checking process, like the procedures to follow, what makes something okay, and if any third-party checking is needed.

- Intellectual property protection:

Agreement on the protection of the branded optician’s intellectual property, such as trademarks, design patents, and confidentiality agreements.

By providing this information in your orders, You can ensure that iDetail have a clear understanding of your requirements and expectations, resulting in a smooth and efficient production process..

(10)Mass-production and quality control

The manufacturer will start mass-production, using the approved making steps, color samples, quality control plan, and order list. They will check and test often during making to keep the same good quality.

(11)Packaging and shipping

Arrange shipping logistics to deliver the finished products to your warehouse or distribution center.

7. Quality Control and Compliance

Keeping high quality and following rules is important for your private label sunglasses business to succeed. Important steps in this process are:

- Quality control inspections: Conduct regular inspections of your sunglasses, both during production and upon receipt, to ensure they meet your quality standards.

- Compliance testing: Ensure your sunglasses comply with relevant safety and performance standards, such as the American National Standards Institute (ANSI) and European Union (EU) regulations.

- Certifications: Obtain any necessary certifications or approvals, such as the CE mark for the EU market, to demonstrate your commitment to quality and safety.

8. Marketing and Promotion Strategies

With your private label sunglasses made and for sale, create and use a marketing plan to get customers and make your brand known. Some good marketing methods are:

- Social media: Utilize platforms like Instagram, Facebook, and Pinterest to showcase your sunglasses and engage with your target audience.

- Influencer marketing: Partner with influencers in your niche to promote your sunglasses and reach a larger audience.

- Content marketing: Create engaging content, such as blog posts, videos, and lookbooks, to showcase your sunglasses and provide value to your audience.

- Public relations: Reach out to media outlets and bloggers to secure coverage and generate buzz around your brand.

Paid advertising: Invest in paid advertising, such as Google Ads and social media ads, to drive traffic and increase sales.

9. Distribution and Sales Channels

Setting up a good way to sell and deliver your private label sunglasses is important to reach your target customers. Some popular ways to sell are:

- E-commerce: Set up an online store to sell your sunglasses directly to customers, utilizing platforms like Shopify, WooCommerce, or Magento.

- Marketplaces: List your sunglasses on popular online marketplaces, such as Amazon, eBay, and Etsy, to reach a wider audience.

- Wholesale: Partner with retailers and boutiques to sell your sunglasses in brick-and-mortar stores, expanding your brand’s visibility.

- Pop-up shops and events: Participate in pop-up shops, trade shows, and other events to showcase your sunglasses and engage with potential customers.

10. Customer Service and Building Brand Loyalty

Giving great customer service and making customers loyal is important for your private label sunglasses business to succeed in the long run. Some ways to do this are:

- Easy returns and exchanges: Implement a hassle-free returns and exchanges policy to ensure customer satisfaction.

- Responsive customer support: Provide prompt and helpful customer support through various channels, such as email, phone, and social media.

- Personalized experiences: Offer personalized experiences, such as custom engraving or tailored product recommendations, to make your customers feel valued.

- Loyalty programs: Develop a loyalty program to reward repeat customers and encourage them to continue supporting your brand.

11.Scaling Your Private Label Sunglasses Business

As your private label sunglasses business grows, keep checking and changing your plans to keep moving forward. Some important things to think about are:

- Expanding your product line: Introduce new styles, colors, and materials to keep your customers engaged and attract new audiences.

- Diversifying sales channels: Explore additional sales channels, such as international marketplaces or retail partnerships, to increase your reach and revenue.

- Streamlining operations: As your business grows, invest in tools and systems to streamline operations, such as inventory management software and automated marketing tools.

- Building a team: Hire staff or outsource tasks to ensure your business can scale effectively and maintain its high level of quality and customer service.

12.Conclusion

- Knowing the Market and Making a Brand Image

Making a private label sunglasses brand needs a mix of ideas, new thinking, and smart planning. By knowing the market, making a strong brand image, working with a good sunglasses manufacturer, and using great marketing and sales plans, you can put your business on a path for lasting success in the tough sunglasses market.

- Caring about Quality and Making Customers Happy

With hard work, not giving up, and caring about quality and making customers happy, you can change your love for glasses into a growing business.