Achieve Sustainable Growth

Your Premier Sunglasses Manufacturers for High-Quality Eyewear

One-Stop Solutions

Concepts Become Reality

As a reliable OEM and ODM Sunglasses Manufacturers, iDetail Eyewear Manufacturer specializes in producing eco-friendly, high-quality eyeglasses frame. We utilize the best materials and stick to ideal manufacturing processes to create unique eyeglasses.This system allows us to offer competitive pricing and low minimum orders. Specifically, our services cater to brands seeking the very best in eyewear products and manufacturing solutions.

Outstanding Eyewear Manufacturing Quality

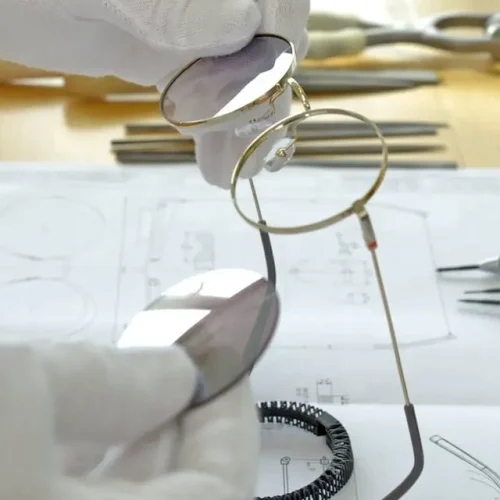

In eyewear manufacturing, we regard the pursuit of quality as the most important task and our lifelong dedication. During the manufacturing of our frames, every step in each glasses frame is carefully inspected by hand by experts who have dedicated their lives to quality control. This is our method and control process to ensure perfection and maintain the exceptional quality of iDetail Eyewear.

Highest Eyewear Industry Standard

We believe your eyewear deserves the best. That’s why every one of our premium frames and sunglass lenses is meticulously crafted and tested. Ensuring that while industry compliance standards continue to rise, our quality always exceeds current and future expectations.

Maybe you will face challenges and difficulties when Creating your own sunglasses brand. Aside from marketing and designing sunglasses, manufacturers’ professionalism, communication, cost, lead time, and IP protection may concern you.Recognizing this, we understand put an end to these issues is key to ensuring your brand’s success.

We invite you to join us! We focus on manufacturing high-quality eyeglass frames by combining eyewear manufacturing knowledge and resources.

A Trusted Partner with Over 13 Years in Sunglasses Manufacturing

Eyeglasses brands are facing challenges such as cost-cutting, scaling up, and keeping up with fast fashion trends. In addition, the quick growth of Chinese sunglasses stock marketing presents another hurdle. As a top sunglasses manufacturer offering high-quality products, competitive pricing, and speedy delivery services to help brands grow.

With 12 years of experience as a manufacturer of high-quality glasses frames, having made millions of eyeglass frames for brands worldwide. Our core capabilities include:

Quality You Can Count On

Our top priority is a glasses quality control system that records every step, ensuring quality control for raw materials, semi-finished and finished products. We ensure the quality of each and every item of products showing customer happiness.

Clear Communication

Professional and straightness work closely with you to understand your needs and provide regular updates on the progress of your order. 24 hours * 7 days a week to ensure that our clients always have access to the support they need.

On-Time

Timely delivery is key and we keep our word to ensure customer satisfaction by consistently shipping samples and goods on time. We maintain a strong sense of responsibility and actively prevent any deviation from our agreement.

Your Vision Our Expertise

ODM manufacturing solutions meet your unique needs and respect your intellectual property rights. Skilled professionals and advanced technology ensure high-quality glasses. Reliable services and ethical business practices build lasting relationships.

Why Choose Us As Your Design Sunglasses Manufacturer?

The market is changing and competition is getting stronger. To succeed, high quality sunglasses manufacturers need to focus on providing the best service, being efficient, and making high-quality products. We should also work on improving services and sunglasses production processes to make glasses products better and faster.

As a high-end sunglasses factory in China, iDetail Eyewear is an ideal manufacturing partner for many eyewear brands. The reason is as follows:

1. Premium glasses manufacturing process and quality

The key to making glasses faster and better quality is to design and optimize the production process. Our expert team uses careful management and the latest technology to produce high-quality sunglasses with great attention to all detail.

During the glasses-making process, we focus o quality control since it defines the product’s quality. We run over 60 checks to ensure high-quality standards and defend a defective rate below 0.035% for your glasses products.

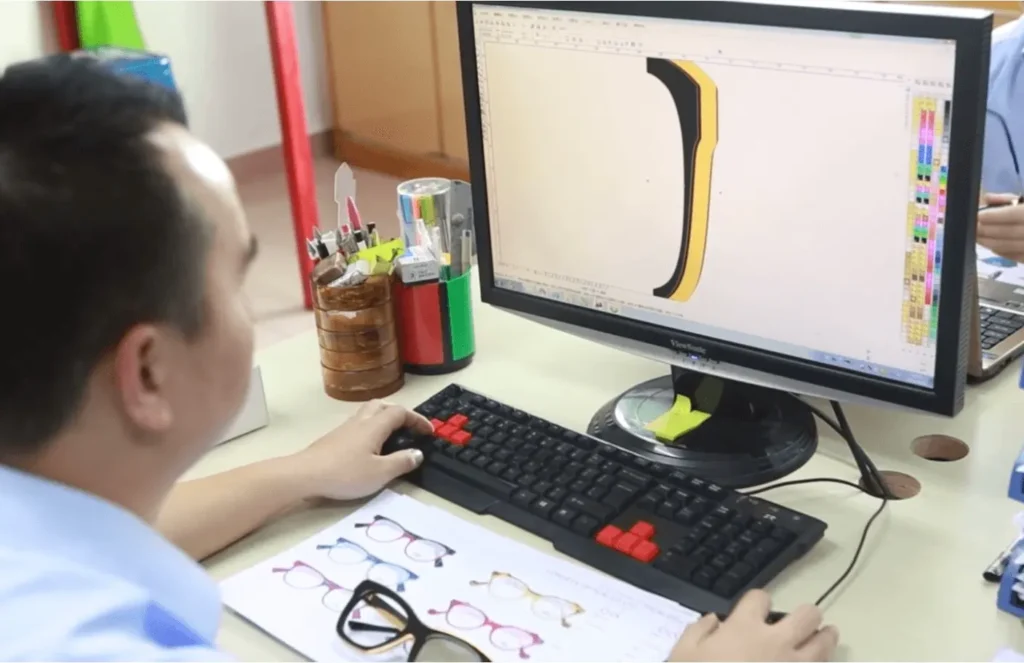

2. Specialized Designing Sunglasses

Our design and engineering teams can take your vision from concept to beautiful eyewear. At the same time, communicate closely with you to ensure 100% Custom. Unique eyewear styles for your brand’s target clients, and run all the brand details.

3. Flexibility and Custom in Eyewear Manufacturing

We offer manufacturing services for over 400 acetate and metal frame colors for custom shapes, materials, branding, and lenses. For OEM clients, we carefully run all details of your brand and produce small test batches or large orders.

4. Cost-effectiveness of eyewear making

We simplify the organizing of glasses parts manufacturers and eyewear raw material factories, reducing costs by up to 13%. Therefore, we make sunglasses at the best prices and ensure the high quality of the eyewear.

5. Sunglasses Manufacturers Reliability

We have a strong record of on-time delivery of quality products. Better eyewear quality systems and professional communication ensure good production and manufacturing.

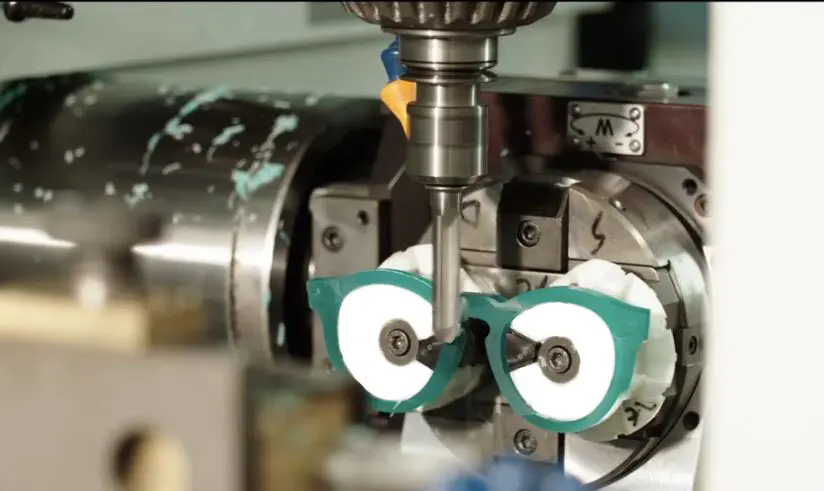

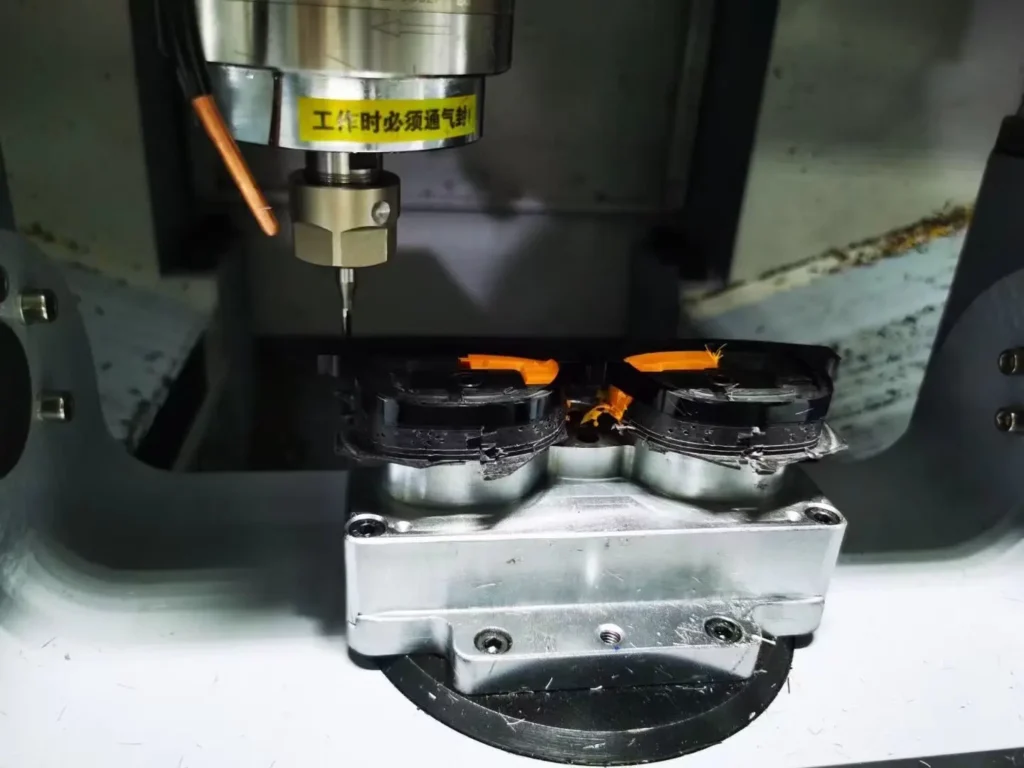

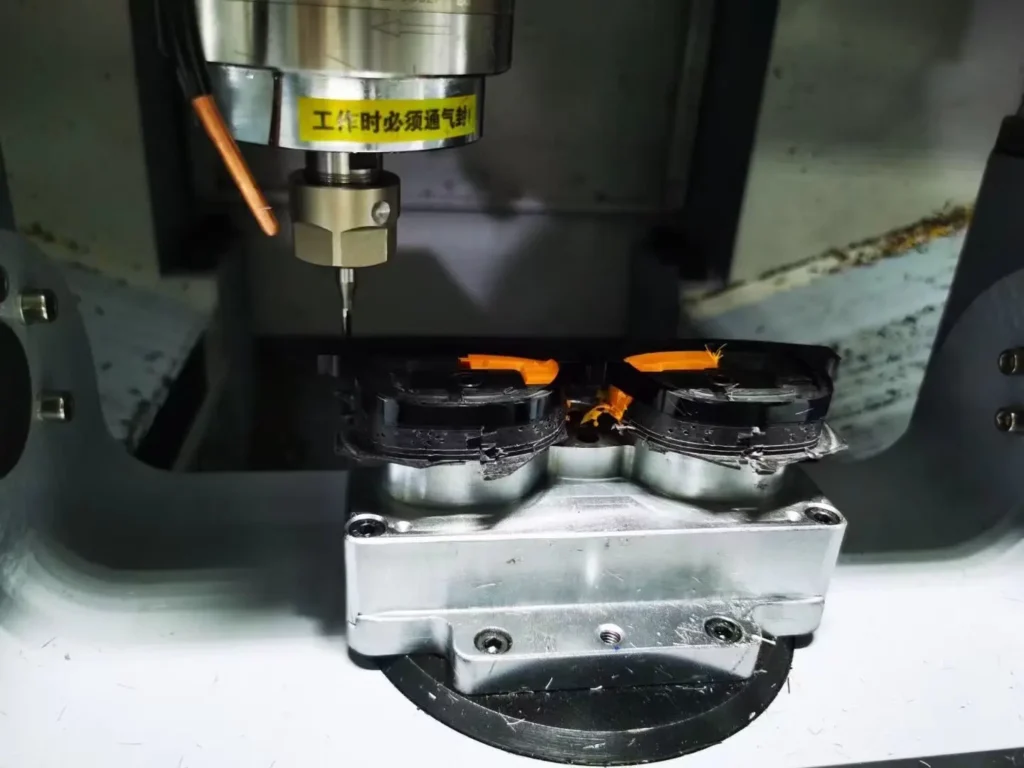

Our Eyewear Manufacturing Powers and Machines

As a professional high end sunglasses manufacturer, iDetail Eyewear has purchased enough ECO-friendly, advanced and stable machines with professional technicians.Our key manufacturing powers include:

- CNC machining center: We have 6-axis and 10-axis CNC machine tools, which can make metal molds and acetate frames of any shape and pattern.

- Precision engraving machines: Our 4 and 5-axis engraving machines machine complex details and patterns on metal and acetate frames. They can perfectly solve the problem of fine carving of strange shapes.

- Precision engraving machines: Our 4 and 5-axis engraving machines machine complex details and patterns on metal and acetate frames. They can perfectly solve the problem of fine carving of strange shapes.

- Laser Engraver: Our 4-axis laser engraver finely carves your pictures and branding elements anywhere on the eyewear.

- Lens cutting machine: We use advanced 4-6 axis cutting for the perfect lens shape. They can perfectly match the glasses frame, is not easy to peel off, and the force is uniform without embossing points

- Tumblers and Polishers: Metal and acetate glasses frames are polished to a shiny finish with eco-friendly polishing machines, greatly improving quality and visual appeal.

- Digital inkjet printer: In order to print patterns, logos, and other fashion elements on the lens or glasses frame, we use the latest digital inkjet printer. The surface effect is delicate and the sticking is strong.

We continue to support workers’ training, update standards, and upgrade technology with equipment to meet the growing need for creation and quality in sunglasses manufacturing.

Range of Eyewear Materials We Manufacture

iDetail Eyewear offers customers a wide choice of high quality frame materials:

- Acetate: More than 400 acetates in solid and translucent shades, right for any style and vibrant color, are the material of choice for high-end eyewear. We source our material from leading acetate suppliers such as Mazzucchelli.

- Titanium: Lightweight, nickel-free, strong, and hypoallergenic, titanium eyewear is a perfect choice for high-end eyewear.

- Stainless steel: light stainless steel, high-flexible stainless steel, we will use high-quality stainless steel materials according to the structure of the glasses, so as to maximize the brightness of the surface.

- Aluminum: Lightweight and corrosion-immune aluminum is fit for commercial and sports eyewear designs. Different surfaces plus anodized color for a stylish look.

- TR90 Nylon: Especially flexible, long-lasting, impact resistant, and lightweight. It’s perfect for high-quality outdoor sports glasses. And the price of the TR90 frame is competitive.

- Wood: Natural woods like bamboo and nanmu add a unique aesthetic to handcrafted high-end eyewear. We can perfectly combine wood with other materials to bring a different touch.

- Combination Eyeglass Frames: Creatively mix metal, acetate, and other materials to create fashionable and usable glasses frames.

We skillfully eyewear manufacture these and other unique materials such as buffalo horn, shells, and more. Our engineers ensure that each material is optimally used and perfectly matched to represent your brand image.

Our Step-By-Step Sunglasses Manufacturing Process

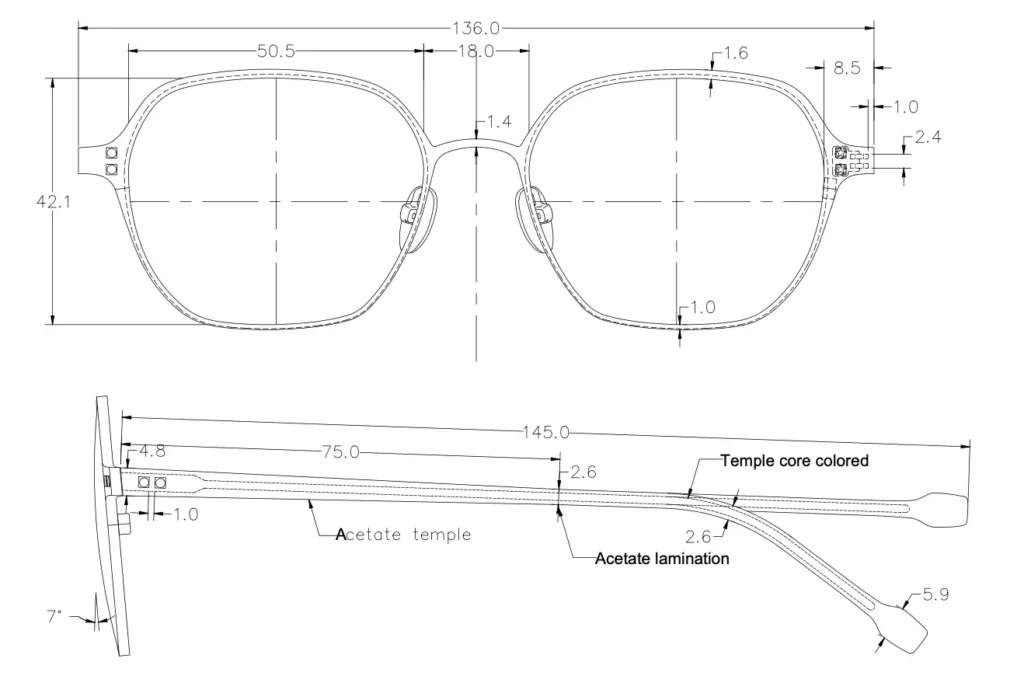

Study of iDetail Eyewear manufacturing and discover the making process behind our tip eyewear. From designing sunglasses, confirming production, and controlling quality, we pay careful attention to every detail from ideas to creating high-quality eyewear.

Moreover, the eyewear manufacturing process involves a feasibility review before production, professional process design, correct size assurance, and a good fit between parts. Totally over 200 steps to ensure high-quality and long-lasting eyewear.

Join us, experience the iDetail difference, and elevate your brand with high-end eyewear.

Key Factors for Manufacturing High-End Sunglasses

In order to be specialty and unique, we must be different. Producing high-quality eyeglass frames need care some factors. A high quality sunglasses manufacturer must be careful to do it and make high-end standards. Below are the key factors we consider when making eyeglasses.

Designing Sunglasses: Style Positioning, Functionality, Comfort, and Aesthetics

- Design is the most important of frame quality and eyeglass frame manufacturers must pay close attention to it. High-quality frames should have a clear style positioning to meet the needs of different consumer groups.

- Meanwhile, the frames’ shape and color should be good-looking, supplying customers with a unique visual experience.

- In addition, frames should have good functionality, comfort, and aesthetics. Designers at high quality sunglasses manufacturers must know the market and fashion trends to create in-demand frames.

We can learn more from popular independent brands and sunglasses manufacturers, such as Dita.

Glasses Materials : High-quality materials and high-quality parts

- Currently, commonly used frame materials on the market include metal, plastic, and carbon fiber. When selecting materials, consider product positioning and consumer needs, as each material has its own Pros and Cons.

- Making high-quality glasses frames need best materials and parts.Glasses manufacturers should pay attention to nvironmental protection, durability, and lightweight.

- In addition, frame accessories such as nose pads and screws also need strict quality control to ensure overall quality.

Sunglasses Production Process and Equipment: Optimized process, advanced equipment

- The design and implementation of production processes and techniques are critical factors impacting frame quality. By optimizing production process, eyewear factories can increase efficiency, reduce waste, lower costs, and maintain quality.

- Effective management, use, and care of equipment keep machines in good state and better production during the sunglass manufacturing process. Strict monitoring of the production process further ensures that every step conforms to sunglass quality standards.

- Moreover, eyewear manufacturers must supply worker skills training and review to ensure stability and reliability of the production process.

Glasses Surface Plating: High-quality plating, surface treatment

- The surface treatment of frames directly affects the product’s appearance and service life. High-quality plating can make the frame surface smoother, brighter, and more wear-resistant.

- To ensure a better plating and best adhesion, eyeglass manufacturers should use best plating techniques during surface treatment.

- Moreover, the surface of frames should also have good decay opposition and oxidation resistance to grow the product’s service life.

- Our sunglasses factory pays close attention to quality to ensure perfect promise to you. Rest assured, we’re committed to delivering perfection.

Management Services: Efficient management, cost control, and quality service

- Quality eyewear frame manufacturers should have efficient factory and production management, strict quality standards, cost control, and excellent after-sales service.

- Useful management focuses on customer needs, and improving productivity while ensuring product quality. It also involves unifying and combining all resources.

- At the same time, Companies must offer fast and correct after-sales service to maximize customer happiness.

In summary, As a high-quality eyewear manufacturer, we innovate, improve quality, meet diverse demands, and excel in competition.

Sunglass Manufacturing- Turning Ideas into Products

We’ll check all the details and supply feedback to prepare for mass production, ensuring final products meet clients’ needs.

1. Understand ideas and needs before manufacturing

Before design and production, eyewear makers need to communicate enough with customers. We need to know the basic needs and ideas for the eyeglass frames, including style, function, comfort, and other aspects.

This step is very important. It impacts later design and production directly. Designers need to record all needs of customers in detail. This is to make sure design and production meet customers’ expectations.

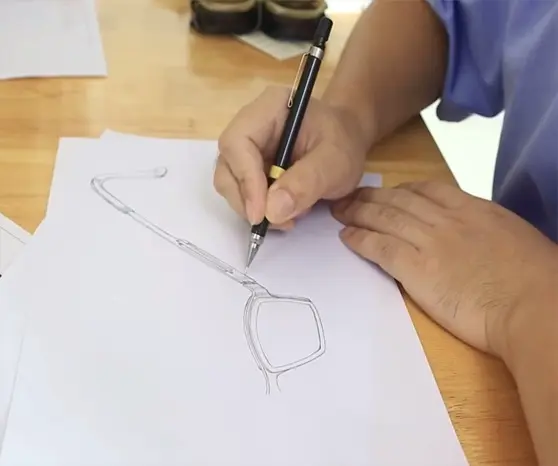

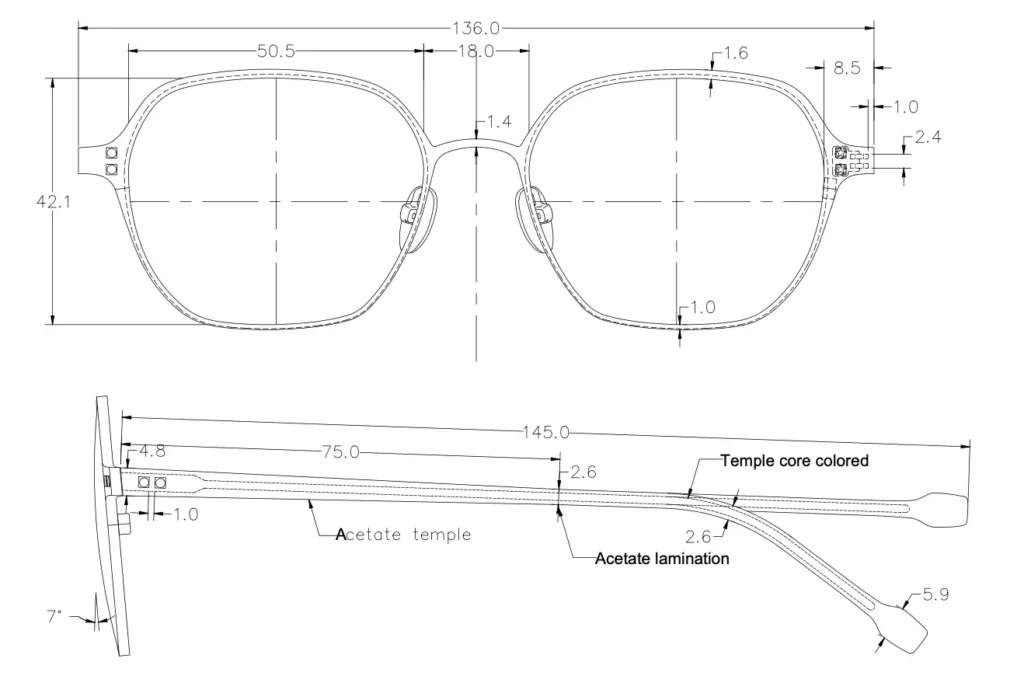

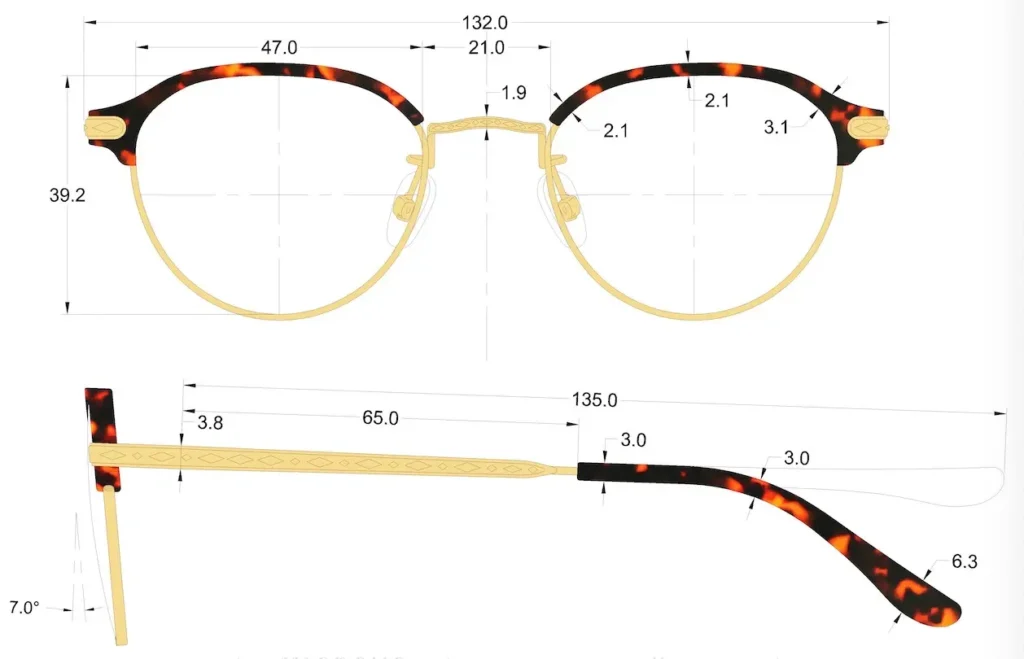

2. Draw and Review Technical Details of Manufacturing

Based on the concepts and needs of customers, eyewear makers need designers to draw Engineering Production drawings. These include sizes, styles, materials, and colors of the glasses.

After the drawings, We need to evaluate if eyeglass frames can be made and ensure no technical problems during production. Any problems need to be pointed out immediately.

3. Customer Review and Feedback for the Drawings

After the eyewear drawings are done, eyeglass manufacturers will send them to customers for approval. If there are any problems, you will give feedback for changes.

Manufacturers will record it and improve the drawings. After several changes, a good drawing will be confirmed.

4. Clients Provides Sample Manufacturing Order

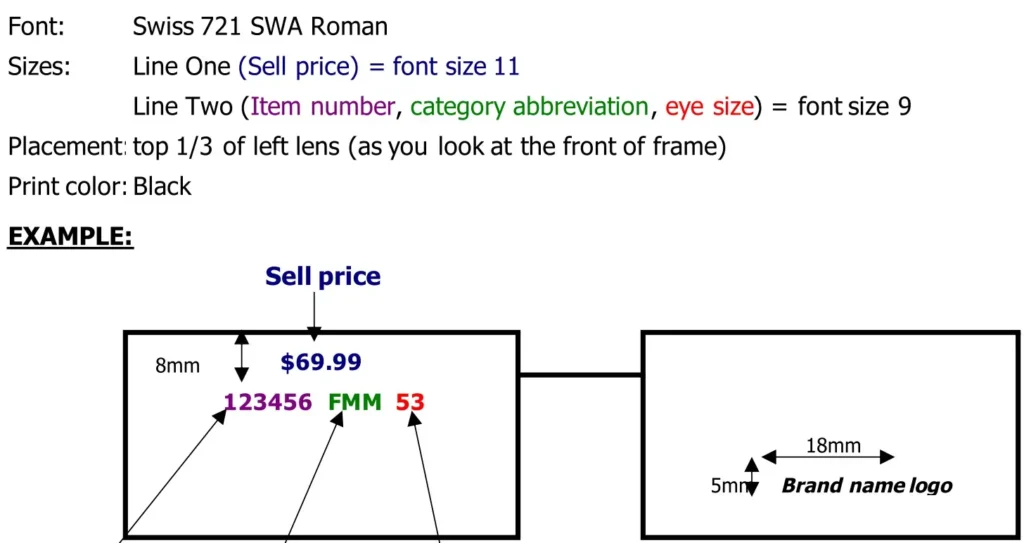

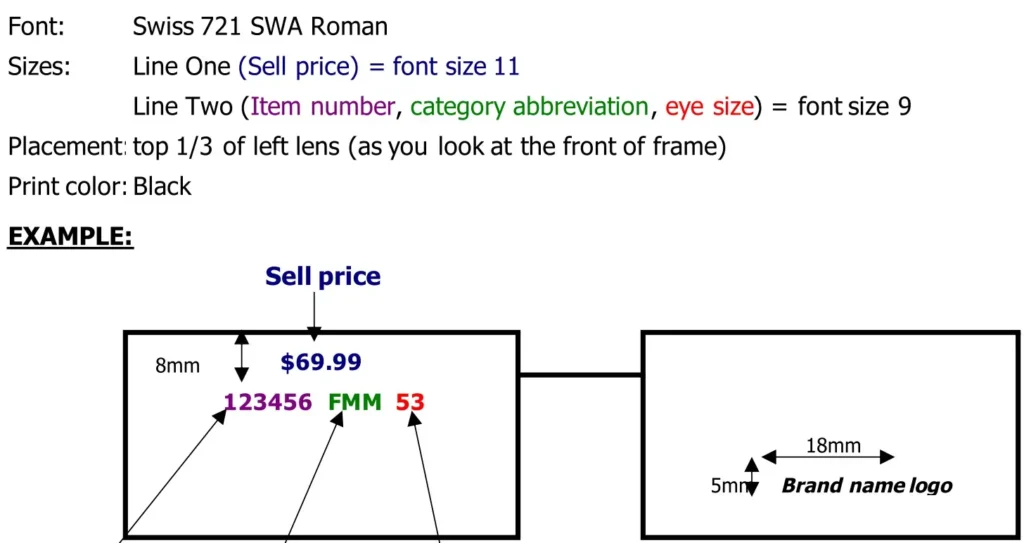

After the drawing is confirmed, clients will give a sample order. The order includes details like colors, model names, markings, etc. And eyeglass makers need to confirm when received the sample order. This is to understand the sample order needs clearly.

5. Making Eyewear Samples and Giving Quotes

According to sample order needs, we will start to make samples. At the same time, study the quotation is based on the sample cost. It is very important to make samples, the main goal is to allow customers to view and check the design very clearly, and the manufacturer will check whether there will be technical problems during production.

6. Customer Sends Mass Manufacturing Order

After samples are confirmed. Customers will place a mass order. The mass order will provide the required information in detail. This includes colors, numbers, delivery time, etc.

After getting it, eyeglass manufacturers need to double-check every detail carefully. We need to raise any questions to ensure the same understanding of the order needs.

7. Eyewear Manufacturer Confirms Delivery Time

Manufacturers need to review the mass order carefully and confirm the exact delivery time. We will check the purchase of raw materials and production schedule. We need to reconfirm a delivery timeline with you that can ensure delivery quality.

8. Eyeglass Manufacturers Plans Production Schedule

Based on order needs, we need to make specific glasses production schedules. These include delivery times of raw materials and time plans for each process. The schedule needs to check the workload balance and ensure all links progress smoothly together.

9. Manufacturer Manages Work-In-Process' Quality

During glasses production, We need to get work-in-process products’ progress and quality condition. Products with issues need to be identified and handled. Managing work-in-process product quality is key to ensuring final delivery quality.

10. Control of production by eyewear manufacturers

During glasses production, We need to get work-in-process products’ progress and quality condition. Products with issues need to be identified and handled. Managing work-in-process product quality is key to ensuring final delivery quality.

11. Manufacturer ships finished product to customer

Deliver the goods to the customer on time according to the agreed schedule. Outbound inspection is required before shipment. This is to ensure that the quantity is correct and there are no quality issues. At the same time, timely delivery notices are issued to help customers arrange delivery.

Why China Is Ideal For Sunglasses Manufacturing

After more than 40 years of fast growth, China eyeglasses manufactures has formed on production, excels in craftsmanship, and high-quality standard. This has build China’s status as a global center of excellence for eyewear production.

1. Talent Advantage in Sustainable Eyewear Manufacturing

China has a more skilled eyewear manufacturing workforce. Since global industrialization and supply chain division, China has developed many management peoples, and skilled workers. This skilled, high-quality, and studious worker is most important for China’s eyewear manufacturing industry.

2. The Most Advanced Eyewear Manufacturing Factories

Chinese glasses factories like ours have heavily invested in the latest equipment required for sunglasses manufacturing. This has greatly improved quality, and efficiency and has trained technical people.

3. Excellent Eyewear Manufacturing Supply Chain

China’s eyewear manufacturing industry has a complete range of types and a solid basis. Moreover, the industrial chain advantage is stronger in the short term. The complete eyewear manufacturing industry chain is one of our great advantages. In China, we can easily get all the high-quality materials, tools, parts, and technologies needed for sunglass manufacturing.

4. Strong Government Support for Eyewear Manufacturing

The Chinese government has supplied useful manufacturing policy guidance. It has also given strong support. This is to develop China into a creation and production base for eyewear manufacturing.

5. Cost Advantages of Sunglasses Manufacturing

In the labor-intensive eyewear manufacturing industry, China has major advantages and a strong floor. After over 40 years of fast development in eyewear manufacturing, China’s worker quality has also improved quickly. Despite growing labor costs, our staff stays competitive compared to Japan, Germany, Italy, the US, and Korea. Also, our technology and quality are catching up.

Compared to rival countries like Vietnam in Southeast Asia, China’s worker costs are a bit higher. But China has the best in the industry chain, worker quality, factory management, worker skills, and hard work. Meanwhile, highly optimized Chinese factories benefit from economies of scale, better taxes, and the best raw material prices.

About iDetail Eyewear Manufacturer

Since 2011, we have been to manufacturing high-quality eyeglass and offer custom one-stop solutions. With an annual production of approximately 360,000 pieces, We specialize in creating acetate, metal, and combination frames. We adhere to all international optical standards, including CE, Reach, Proposition 65, and ANSI. However, we aim to go beyond these minimum requirements and create unique designs and products for our clients.

At iDetail, we believe that perfection in detailing is the key to lasting and growing in the long run. Our popular designs, better touch, and the perfect fit between parts have become a unique element of our sunglass production over the years.

Partner with us for exceptional eyewear manufacturing and experience the difference.

At iDetail, we believe that perfection in detailing is the key to lasting and growing in the long run. Our popular designs, better touch, and the perfect fit between parts have become a unique element of our sunglass production over the years.

Partner with us for exceptional eyewear manufacturing and experience the difference.

Create Your Own Sunglasses Brand With iDetail Manufacturers

Would you like to creating your own brand of sunglasses? The high quality sunglasses manufacturers can help you stand out with One-Stop OEM sunglasses manufacturing services.

We know the eyewear brand reflects your personal style and values. So offer a wide range of custom options, to support you in creating stylish, comfortable, and high-end sunglasses.

We will carefully craft your sunglass using high-end sunglasses materials such as Acetate, Stainless steel, Titanium, and Nylon. They have robust hinges with anti-loosening OBE screws to ensure durability and long-lasting wear.

Our unique glasses designs with your ideas, and high-quality manufacturing ensure that your sunglasses frames stand out.

Choose us as your partner to create your own sunglasses brand. Let us help you bring your vision to life with the best quality and action.

Join hands with iDetail Eyewear Manufacturer