Create Your Own Eyewear With Custom Sunglasses Manufacturers

Do you understand the business process of Custom Sunglasses Manufacturers?Create a pair of well-made custom sunglasses, from conception to final glasses product,through a series of professional control links. These include concept design, eyewear material research, technology development,mold tool design, eyeglass process flow formulation, finishing,and sunglasses quality control system build. Custom sunglasses manufacturers must exercise precise ,and strict control of details to ensure the quality,effect and comfort of the glasses.

iDetail makes your sunglasses perfect!

Choose Your Needs!

Professional and straightforward engineers work closely with you, minds collide,understand your concepts instantly and execute them,translating your ideas and requirements instantly.

TOP priority is Glasses Quality Control System,ensuring every step is recorded and quality control for raw materials,semi-finished and finished products. and the quality of every item and batch of our products is guaranteed.

The importance of protecting intellectual property is a fundamental ethical guideline ,must be established to ensure that production documents,markers,and frames never leak out of our factory.

Timely delivery is essential as per our agreement,with the defaulting party held accountable. To cater to our customers’ needs,we must ensure on time shipping samples and goods.

One-stop custom manufacturing solutions to meet your unique needs,skilled professionals and advanced technology ensure the manufacture of high quality eyewear.

Positive price is crucial to establish a fair partnership,and a clear understanding of the cost facilitates, the establishment of trust and front lines between us,ensuring that our partnerships are more stable and long-term.

Custom Sunglasses Manufacturers

The Process of Custom Sunglasses Manufacturers

You’ll work closely with the custom glasses manufacturer during production, offering input and guidance on details, changes, and implementation. Together, you’ll establish sunglasses production processes and sunglasses quality control methods, ensuring the final eyewear meets consumer needs in your target market.

1. MARKET RESEARCH:

A detailed study of your glasses concept covers strategy, target audience, budget, competition, and current fashion trends in the market.

In early design stages, designers find inspiration worldwide, looking at trends with a fresh perspective to create innovative results. They focus on fashion, architecture, and design as ideas start to form.

2. CONCEPT SKETCH:

Creation and submission of concept sketch which includes construction, shapes, material, color, and design details.

The design phase is critical to achieving a result that reflects the elements and style of the brand logo. The entire process requires close collaboration between the eyewear design team and the client, with designers developing various style models in draft, and then completing the final design artwork based on the eyewear brand collection and visual language.

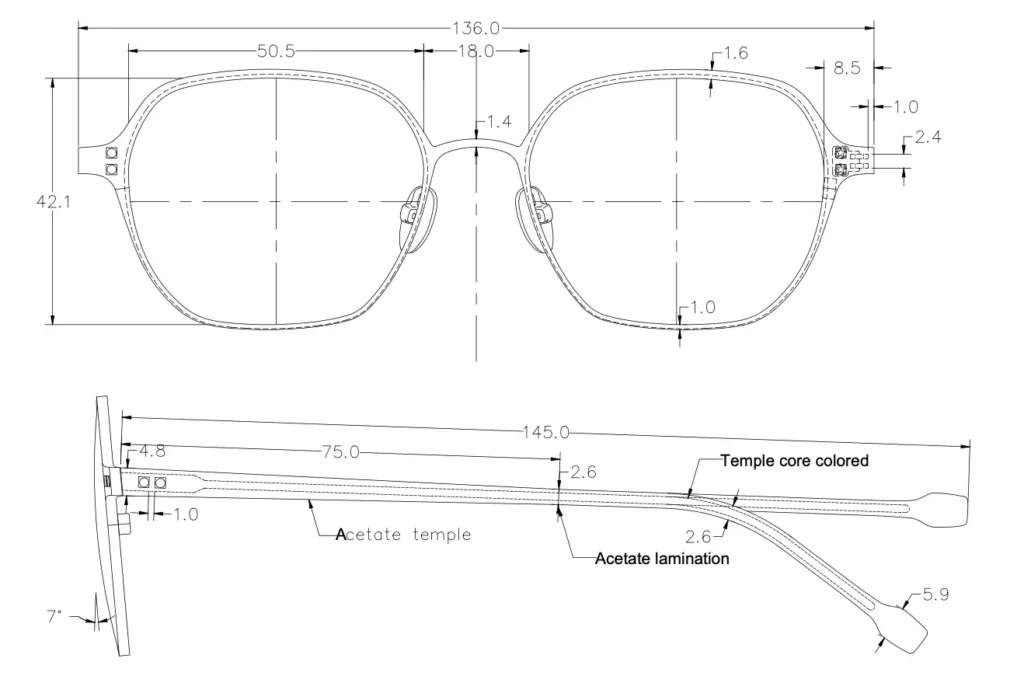

After approval of concept sketch, we develop AutoCad glasses technical drawing to verify dimensions, technical details and specifications for prototyping.

A technical drawing is a representation of the samples being created on the final product. it is important because this is what the factory will follow when producing a frame. If the drawing is incorrect , the sample will be incorrect . Getting approval for a cad will ensure that your sample will be very close to what client is looking for.

4. PROTOTYPE:

Once the glasses technical drawings are finalized, the process moves to the prototyping stage. For each new product, the research and development team creates a physical model, outlining the first frame series. At this stage, craftsmen work with precision, and attention to detail to ensure the structure, quality, assembly, and design meet the client’s requirements and expectations.

Once the prototype receives final approval from both the company and the client, it serves as the main project , and becomes the guiding principle for quality control throughout the certified production process.

5. QUOTATION:

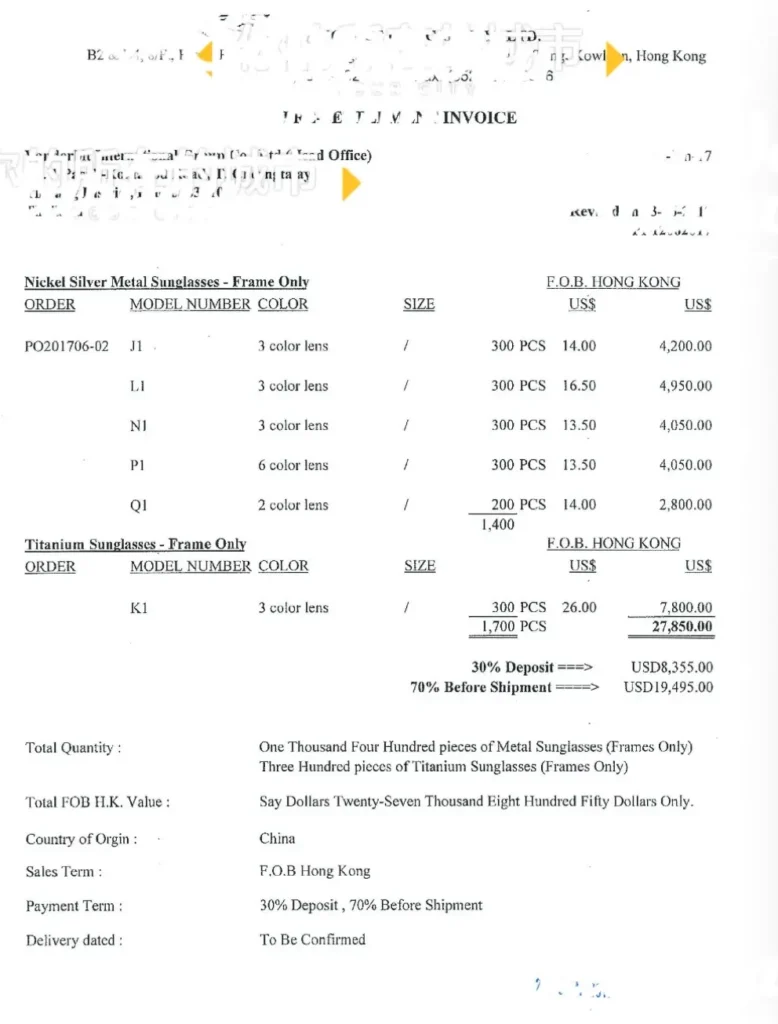

Submission and approval of quotation.

Positive price is crucial to establish a fair partnership, and a clear understanding of the cost facilitates the establishment of trust , and front lines between us, ensuring that our partnerships are more stable and long-term.

Custom Designer Sunglasses

6.PLACE THE GLASSES ORDER:

When Client place orders with Custom Sunglasses Manufacturers, they typically include the following items in their order:

- Detailed information of brand companies and manufacturers

- PO and model NO.

- Product details : bill of materials Detail, color etc.

- Item No.

- Description

- Pad printing or laser brand and model information

- Quantity each color and total quantities

- Unit Price and total (USD)

- Remark

- Payment Term

- Delivery date

7.DELIVERY CONFIRMATION:

Confirmation of delivery date and reception of deposit.

Every detail is the beginning of keeping promises. We must abide by our promises and strictly implement every word and message we reply to our Clients.

This information requires close coordination and consultation between our engineering design department, production team, quality control department , and material partners to ensure that all aspects of the project are synchronized and executed efficiently, plans are developed and reflected upon our receipt of customer orders for inspection, and in the proforma invoice that is confirmed and sent to the customer.

In order to secure an order and start production, we need customers to pay a deposit. This deposit is a commitment by both parties to abide by the agreed terms and conditions , and is a guarantee of the client’s intention to proceed with the project.

8. START OF SUNGLASSES PRODUCTION:

Launching of procurement of materials and sunglasses production.

The production of a pair of glasses requires more than 180 processes. This process requires not only excellent technical equipment, but also a high level of demand on the operator technicians to ensure that the selection of materials , and the execution of the production processing steps are error-free in order to be able to do so.

This process involves close coordination between our engineering confirmation department, production team, quality control department, and material partners to ensure that all details of the production order, and production process, quality standards and related tests are synchronized and effectively executed.

The team will also actively monitor the production process of custom eyewear, maintain consistent communication with customers, provide production status updates, and address any concerns or issues that may arise. Our commitment to transparency , and accountability ensures that our customers are fully informed throughout the process.

9. PRODUCTION SAMPLE:

The Pre-Production Sample is a sample of the products that occur before manufacturing starts. Eyewear manufacturing processes that need to be confirmed before large-scale production begins.

Must be evaluated and approved prior to mass-production. The primary purpose of the pre-production process is the early identification of any problems during actual production, and make the necessary corrections.

ensure that the final product is consistent with the quality, and standards of the original product conceived during the product development process.

10. SHIPMENT:

Shipment of final products.

As eyewear manufacturing draws to a close, the finished product is thoroughly sunglasses quality checked and ready to ship. Ahead of the delivery date, we confirm shipping details , and provide tracking information, enabling customers to monitor the progress of their shipment.

Our goal is to provide a seamless experience from start to finish, ensuring our customers receive custom sunglasses in good condition on time.

High Quality Sunglasses Manufacturers

High quality products from Custom Sunglasses Manufacturers

A good pair of glasses frames should be constructed of safe, quality and functionally reliable, ECO-friendly materials that fit snugly on the face, are sturdy and do not deform.

The use of high quality sunglasses materials is one of the key factors in making high quality glasses. Quality raw materials have higher purity and plasticity, less impurities and purer colors.

In the same process, it can make the manufactured products have higher quality, such as the surface is more shiny, pattern or mark more three-dimensional and clear, it can be said that the quality materials make glasses more touch , and visual high-grade feeling, have the capital to make you fall in love at first sight.

2. Precise production mold

Many sets of molds are needed to make a high-quality metal glasses, the most common ones are the temples and the bridge, some are the frames or some other parts. The quality of the molds directly determines the quality of these parts.

Therefore, we must pay great attention to the production of molds , and pay attention to every detail of the molds. Therefore, we must pay great attention to the making of the mold , and pay attention to every detail of the mold making, precision, finish, etc. Every aspect must be taken into consideration and made perfect. Only in this way, the selected quality material in the mold After pressing again and again, we can make the perfect parts of glasses.

For example, the pattern on the surface of the glasses, first of all, we must make sure that the pattern of the mold is perfect, and every corner of the pattern is smooth and delicate. Therefore, when making the mold, the concave part inside the pattern should be polished again and again.

It is crucial to polish it manually.

3. Polishing of the eyeglasses product

A perfect pair of high-quality metal glasses must have a polished and textured appearance, in addition to a perfect structural shape. The different parts of the metal glasses are manufactured.

After made, they are perfectly joined together by welding machine. Then they are tumbled again and again, and repeatedly hand-polished again and again, until the surface of the metal shines and the shape is square and distortion-free.

In this process, the tumbling machine, the tumbling material, the hand polishing material and the operator’s skill are each aspect is important and attention must be paid to each and every detail.

4. Glasses Customized workmanship

Each metal glasses has its own personality, round, three-dimensional, etc. Different designs reflect different styles, even the same pair of glasses, some parts are three-dimensional, while some parts are round, or other different. style, so in the production process, you have to customize the craftsmanship for each different style of metal glasses to ensure that every detail of the glasses can present the most perfect effect.

For example, a piece of stainless steel sheet metal glasses formed by cutting has a bevel on the front frame. When making this kind of glasses, the general factory cuts the shape and the bevel at one time, and then completes it by rolling and polishing. In the production of glasses, the effect of the beveled surface is not obvious, it looks like a beveled surface, and it also looks like a circular arc surface, which becomes a pair of glasses without personality and soul.

Therefore, you have to separate the production process of the bevel, cut the front frame, and after the first tumbling and manual polishing, the metal surface will become very smooth and delicate. At this time, use the diamond cutting process to make the bevel, and then pass After the tumbling and polishing process, it can be regarded as soulful and perfect high-end metal glasses.

Personalized glasses manufacturing: handmade customized glasses

As the demand for personalization continues to grow, customized consumption is becoming the current trend. However, hand-customized glasses are not a new thing. In ancient times, glasses did not have the conditions for mass production, and hand-customized glasses were the only way to wear glasses.

1. The process of hand-made custom glasses

In modern times, the technology of optometry and lens polishing has gradually matured, and the tools for making glasses have become relatively unified. The process of hand-customizing glasses has also become more and more mature, which mainly includes the following steps:

1.1 Early communication for handmade customized glasses

The optician will fully communicate with the customer, assess their needs, and provide multiple basic design plans to choose from;

1.2 Measure relevant dimensions for custom glasses

Measure eye data such as myopia, hyperopia, astigmatism, as well as head size, nose bridge height, cheekbone height, nose bridge width, etc. to determine the size of the frame and temples.

1.3 Personalized finishing of custom glasses

After the approximate size is determined, in order to optimize the wearing comfort, based on the customer’s personalized problems, such as glasses clip, slippage, and deflection, the body data is carefully measured again, the sample is repeatedly tried on, and the drawings are modified.

1.4 Choose materials and accessories for custom eyewear

Precious metals, ivory, horns, cowhide, wood, tortoise shell, gemstones, etc. are all optional materials for glasses. Some high-end glasses shops with special craftsmanship will also provide engraving and nameplate services.

1.5 Make a sample of custom glasses

After all the parameters are determined, a first version is made with basic materials and fitted with lenses to become suitable trial lenses. Final modification opinions will be formed after trial trials and feedback.

1.6 Hand processing of custom glasses

Use selected materials to create the final product.It can be seen that in the past, the customization cycle of glasses was long, and the relationship between the optician and the customer was far beyond the ordinary relationship between buyers and sellers. In addition to the cost of materials and workmanship, the high customer price also included this strong personal service attribute of the old era.

Handmade custom glasses gradually becoming popular

With the advancement of material technology and processing technology, custom glasses are turning to lightweight and durable materials, paying more attention to the wearer’s comfort needs and compensating for physical defects, with the main pursuit of providing customized vision correction. And provide the right amount of styles, colors, and sizes to choose from.

At the same time, the SKU of customized glasses has been greatly enriched. Some brands have launched special styles such as Asian models, European models, large and small sizes, etc. It only takes a little time to combine different specifications with the help of an optician consultant/salesperson. This semi-customization of standard parts is called “customization.”

The selling points of today’s handmade custom glasses are tailor-made, unique shapes and sizes, rich material combinations, and the psychological value of pure hand processing.

Handmade custom glasses of the future

The customizable nature of eyewear comes from its precise fit and decorative properties for correcting vision. Handmade customized glasses from ancient times to the present have also been developed around these two points: tailor-made and precisely crafted to provide the wearer with the best fit and most comfortable wearing experience; independent selection of shape and material also brings the ability to highlight identity and Highlight the mental value of individuality.

Just imagine, if you pursue the ultimate precise fit, the most accurate vision correction and wearing comfort, what kind of customized glasses will you get? Today’s technology gives us the opportunity to enjoy the ultimate fitting and unique wearing experience – 3D printed glasses, with the help of facial scanning technology, computer-aided modeling technology, and 3D printing technology.

In summary, Custom Sunglasses Manufacturers excel in crafting unique, high-quality eyewear by adhering to a rigorous business process. We emphasize precision and strict control of details throughout each stage, ensuring the final product delivers the desired comfort, effectiveness, and quality for consumers.