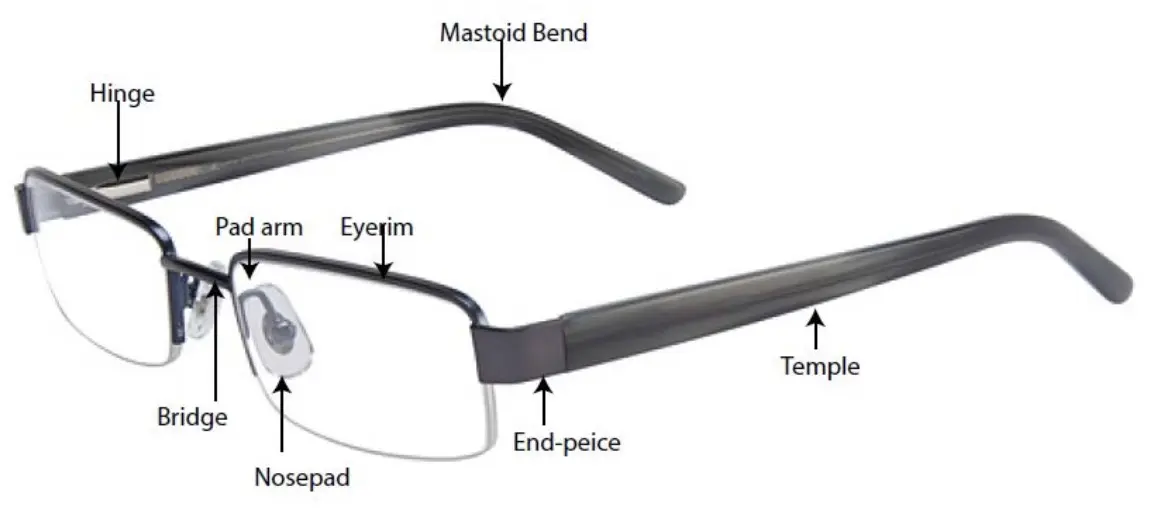

Parts Of Glasses

Have you ever considered the parts of glasses or sunglasses? Friends often ask sunglasses manufacturers what glasses are made of? What are they called? What type? In fact, glasses are not only frames and lenses, also many small size parts. and they all have own names and functions., Knowing them helps to better designing sunglasses and make sunglasses technical drawing.

Sunglasses production is a complex process that demands attention to detail. Despite their compact size, each part a crucial role in creating a durable, comfortable, and stylish final product. Ensuring that all parts work seamlessly together is vital, and utilizing high-quality glasses materials for the various parts is essential to manufacturing high-end eyewear.

If you want to learn more about Parts Of Glasses, you are in the right way.

What are the parts of glasses called ?

1. Rimlocks

The rim lock is a small part that attaches to the eye-rim of eye glasses and the end-piece of metal temples,Its primary function is to close the open eye-rim and facilitate the easy soldering of the temples’ end-piece onto the eye-rim.

- General rimlocks :To loosen the rimlocks and then disassemble the lenses, so rimlocks are very important part and must be made of 18Ni to 22Ni Monel.

- Vertical rimlock:The vertical rimlocks is also characterized by three parameters, i.e., the length of the clamp opening A, the width of the grade B, and the depth of the grade C. The vertical clamp has no slope, such as vertical 3.2 × 0.8 × 1.8 and vertical 3.8 × 1.2 × 1.8, etc.

- Vertical edgeless rimlocks :A standing edgeless high rimlocks is shaped like a common rimlocks with the edges removed and welded vertically. Since there is no edge and high, the soldering position can be varied without restriction and is often used for sheets frames of eyeglass frame structure.

2. Rim

The Metal Rim is a wrapping eyeglasses part that surrounds the perimeter of a lens, typically made of metal and also referred to as the eye wire. It usually features grooves on the inside for securing the edge of the lens, with a smooth or specially textured exterior.

Vintage embossing and surface coloring have recently become popular options as well. The material used for the rim must have a high degree of purity to ensure strong welding. The size of the rim’s interior circumference must be precise to prevent deformation when installing the lens.

Rims come in varying sizes, specifications, and patterns, with different selections made based on the frame’s structure and intended use for eyeglasses or sunglasses. Primary materials for rims include white copper, stainless steel, and titanium.

- Flat-backed V-shaped eye rim

The inner pit of the eye rim cross-section is V-shaped, and the outer face is flat. The front face is 90° from the outside face, and the inner pit V-shape angle is 110° and 90°.

- round-backed V-shaped eye rim

with rounded outer surface, otherwise the same as flat-backed wire, and the same specifications as the flat-backed eye rim.

- Flat-backed U-shaped eye rim

The inner pit of U-shaped wire is rectangular, and the outer side of the wire is the same as the flat-backed rim. The size of the

U- shaped inner pit is about 0.6 X 1.2. The size of the U-shaped rim and the material used are the same as for the flat-backed V-shaped eye rim.

- Fish shredded eye rim

The cross-sectional shape of eye rim is shown in the figure below. It is specially used to produce half-frame. The inner pit is a -T shaped groove, which is used to clamp the inner wire and achieve the effect of fixing the lens.

- T eye rim

The section of T eye rim is T-shaped, and it is also specially used for half-frame. This kind of eye rim does not need to wear inner wire, and the lens is directly clamped on the T-shaped convex rib of the rim.

This kind of rim uses the least amount of material, and is generally made of stainless steel or titanium. It has the simplest and lightest shape and structure, and is often used in the production of women models. But the eye rim is difficult to process.

3. Pad Arm

The component that connects the eye wire and the nose pads (also known as the nose pad arm because of its resemblance to a pipe) is joined through precise welding techniques. By bending this part, the position of the frame relative to the face can be adjusted for a more comfortable fit.

- The pad arms undergo different processing techniques depending on the material and type of glasses frame. In plastic frames, they are generally riveted underneath the beam of the frame or embedded into the frame through a process called inlaying.

- Metal eyeglass frames are typically welded directly onto the eyewire. If the frame is made of aluminum alloy, it may instead be attached using rivets.

- Although the nose pad arms are just a small part of eyeglasses, they are closely related to the wearer’s comfort during use. If they are not adjusted properly, it can greatly affect the wearer’s comfort.

- pad arms material :The requirements for the material of the pad arms are relatively high. It is necessary to take into account the plasticity and toughness to ensure the need for bending. At the same time, the strength (hardness) of the material is required to be high, and the welding performance is better. Therefore, the material used for the general pad arms is high nickel. Cupronickel wire or manganese wire. The thickness of the wire material is generally 1.0~1.2mm, and it can also be made of 0.8~1.0mm stainless steel wire under special requirements.

4. Bridge

The bridge connects the two eye rim or lenses and supports the glasses on the wearer’s nose. Size is crucial, and combined with the nose pads, it directly affects the comfort of wearing glasses.

The bridge must be positioned symmetrically in the center between the two eye rim or lenses. Therefore, it is a crucial component in eyeglass design. It is typically made of hard and sturdy materials, but some designs use materials with excellent rebound properties.

There are different bridge designs, including single and double arch, as well as integrated retro designs that combine the bridge and nose pads.

If the cross-section of the bridge is only small, MONEL material or stainless steel material with better strength should be selected; if the surface shape and pattern are complicated, it should be selected use cupronickel, high-nickel cupronickel or MONEL-material with better hydraulic performance.

MONEL material is a material with very good comprehensive performance, and it is the most commonly used material for manufacturing bridge. Titanium and titanium alloys are used to manufacture high-end glasses frames.

5. End Piece

End Piece (Lug) have the same function, they are both located at the corner of the eyebrows of the frame, connected with the eye rim and temple. It is an important part of eyewear design, and requires a certain level of hardness to ensure that the frame does not deform..

Generally, those with simple shape and small size are called end pieces, and those with complex shape and large size are called lug. The shape of End Piece and lug requires the front end to match the circle shape, and the back end to match the temple.

End Piece (Lug) is welded with eye rim, so the welding performance of its material is better, otherwise other connection methods are required. Commonly used materials for making End Piece (Lug) are: cupronickel, high-nickel cupronickel, manganese, stainless steel, cast copper, etc.

6. Temple

The temple, also known as the “glasses arms” or “legs” of the glasses, is located at the back of the frame and together with the frame and hinge, forms the eyeglass frame.

It has a curved shape at the end, which rests on the ear and, together with the nose pad and bridge, provides support and stability to the glasses when worn, making it an essential component of the glasses.

Commonly used temple materials are: brass, white copper, high-nickel white copper, manganese, stainless steel, pure pot, lead-magnesium alloy, titanium and titanium alloy, bamboo wood, resin, etc.

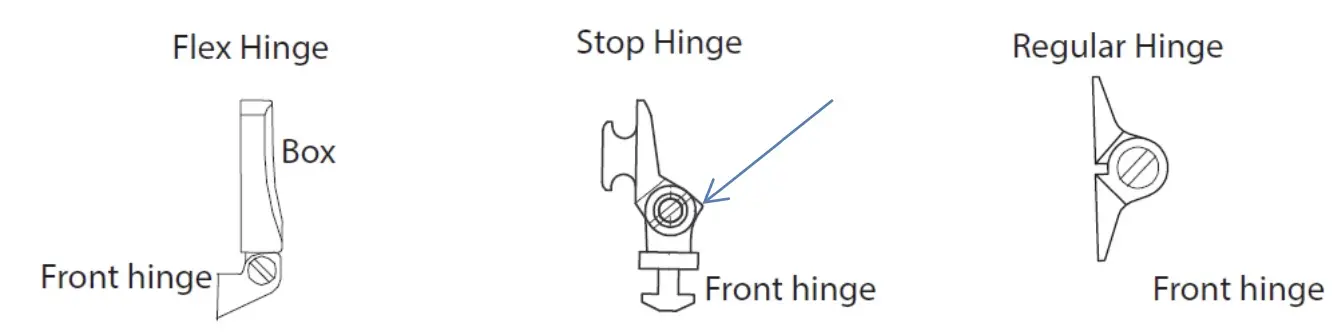

7. Hinge

For Flex hinges, we expect our frames to comply with the double spring action test, which is when the temples are closed and opened, then opened an extra 18-20 degrees and closed 30 degrees and still return to its original position. The spring action must always have a smooth movement and open/ close freely. Our preferred suppliers are obe and visottic agroup。

Flex hinges are preferred on compression mount frames to relieve stress at the drill points, however too much flexing can cause cracking at the drill holes.

Stop Hinges are preferred for sunglasses since the temples may touch the back of the lens.

Regular hinges are used when a flex hinge or stop hinge is not required or necessary. For wider temples, 5 barrel hinges are required to prevent unnecessary rocking.

Regular hinges must withstand 18-20 degrees of extra opening at the temple angle and after test will return to original state without deformation.

The hinge must perfectly match without a gap or temple movement.

- Standard hinges:

Standard hinges (also known as barrel hinges) are the most common type of eyeglass hinges.Standard hinges are durable. These hinges have been around almost as long as eyeglasses have been.

- Spring/Flex Hinges:

Known for its flexibility, the spring or flex eyeglass hinge offers the active wearer a snug fit that doesn’t pinch. Unlike standard or barrel hinges, spring/flex eyeglass hinges come with an attached spring that allows them to bend past ninety degrees.

The spring itself takes the majority of the force when the glasses bend and twist, allowing this type of hinge to retain its initial balance and fit without the need for subsequent adjusting.

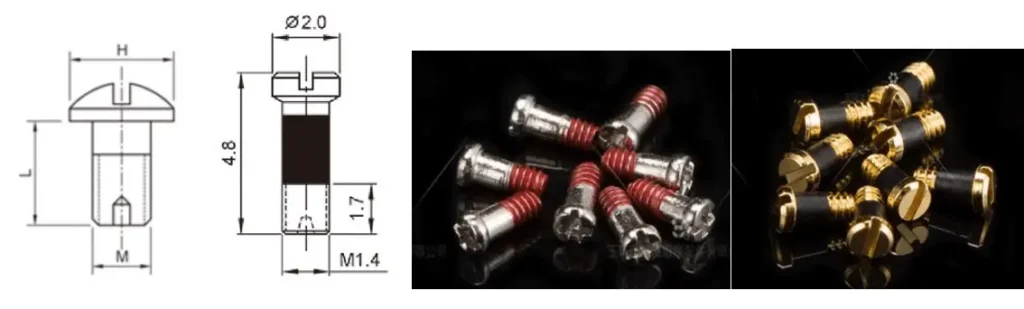

8. Screw

In the glasses industry, there are four general types of screws:

According to the use of screws: hinge screws, rimlocks screws, nose pad screws, and screw holder screws.

According to the shape of the screw head: flat head screw, round head screw, headless screw and hexagonal screw.

According to the groove type of the screw head: slotted screw, Phillips screw, and slotless screw.

According to the difference of screw teeth: half-thread screws, full-thread screws and self-tapping screws.

- RIMLOCK SCREWS

Rimlock screws are required to be stainless steel, minus (-) head safety (coated) screws that are milled for all glasses product. Safety screws must be applied to the frame AFTER the coloring process so the screws do not get fused into the rimlock and result in a defect known as “frozen screws”. Loctite MUST NOT be used.

The rimlock screw end should protrude approximately 0.2 mm to 0.3 mm.

- HINGE SCREWS

Hinge screws must be partially threaded to help avoid backing out over time and causing the hinges to loosen. In addition, hinge screw size should be M 1.4 mm. For glasses product, the screw end should protrude approximately 0.2 mm-0.3 mm and self-locking screws should be used.

Safety screws should be inserted only after electroplating so the screws do not get frozen.

- TEMPLE SCREWS

Any screw on the inside temple of a frame must be minus (-) head. For screws that would come in contact with the opposite temple when temples are closed, please countersink them below the temple surface to avoid scratching the opposite temple when closed.

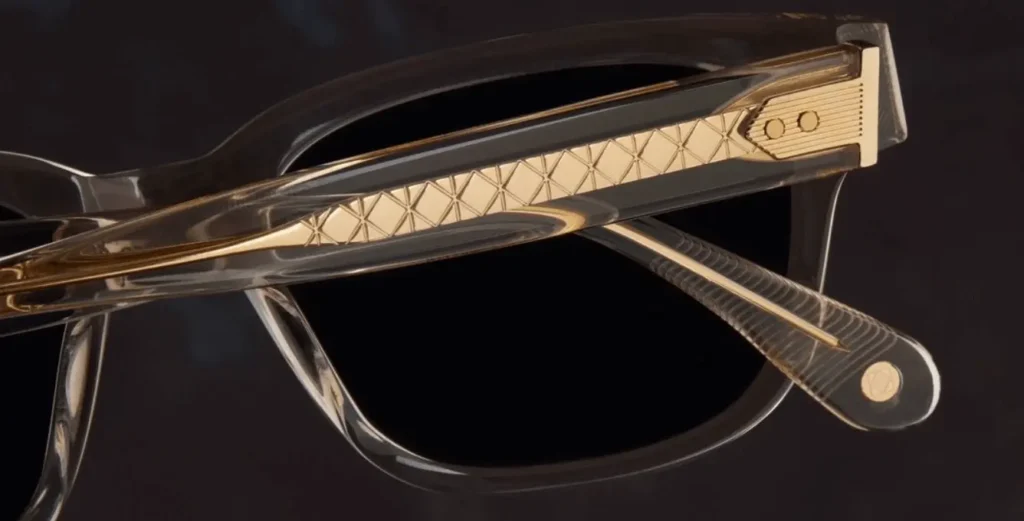

9. Top Bar

The top bar of the glasses is mainly used for decoration, which can better reflect the calmness and atmosphere of the wearer.

The earliest creation of this kind of glasses was in 1938, released by Ray-Ban Company, so it is also called “aviator glasses”. At first, this double design was mostly used in sunglasses.With top bar design is very cool and stylish.Not only is it stylish, but also the stability is better than ordinary sunglasses, and it will not often fall off when participating in outdoor activities.

10. Core Wire

Core wire is an important part of the frame of the glasses, helping the temples of the glasses to retain their shape and connect to the lenses. Core wire glasses, or glasses with exposed core wire temples and a slight metallic frame encompassing the lenses, are becoming increasingly popular, often used to create a more delicate, vintage appeal to the look of the glasses while maintaining the overall shape of the glasses.

11. Nose Pad

The Nose Pad are an indispensable part of the finished spectacle frame. They are installed on the wine glass to support the weight of the glasses. The size, shape and material of the stipules have a direct impact on the wearing comfort of the glasses.

- Structure of nose pad

The shape of the stipules is like a leaf, and there is a mounting lug in the middle of the bottom surface of the nose pad. The lugs are divided into two types with holes and without holes, which are respectively matched with the upper screw nose pad and the clip-on nose pad. There are two types of lifting lugs: metal and non-metal. One end of the metal lifting lug is injected into the center of the nose pad, which is often called a metal core nose pad. This kind of stipule is the most widely used.

- material of nose pad

Commonly used nose pad are: real silica gel, imitation silica gel and PC material. Silica gel is a very soft and elastic material, and it is non-allergic to human skin. It is an ideal nose pad material and is the most widely used. In addition, rubber is sometimes used as a nose pad material. Such as jade and titanium are now developed.

- All nosepads, whether branded or unbranded must be within the limits allowed by the EU directive 76/769/EEC, REACH, and Proposition 65 requirements, as well as be UV resistant.

- The suggested sizes for unbranded nosepads are:

• B dimension smaller than 40 mm, use a 12-13 mm nosepad

• B dimension larger than 40 mm, use a 15 mm nosepad

- There are two types of metal pad arms that are generally used-European or regular pad arms and gooseneck or pigtail pad arms. Gooseneck or pigtail pad arms are used for alternate fit frames. The nosepad screws must also be minus (-) head.

12. Temple Tips

The name of the ear hanging part at the back end of the temple (the invisible part after wearing, it is a very important part), mainly used to adjust the length and angle. In addition, by adjusting the weight of the temple tips, it will also improve the wearing comfort. so careful adjustments must be made during the fitting process of the glasses.

Generally speaking, there are use acetate materials to cover metal, or injection molding materials to cover metal, and there are also all-metal temple that create an elegant temperament and a sense of luxury.

13. Lens

Many of Brands use similar lens colors and materials. Optical clarity and the ability to pass all sunglass standards (ANSI Z80.3, ISO 12312-1 and AS/NZS 1067) is a major factor in our approved lenses.

Any sun lenses that protrude out of the back of the eyerim should be have a safety bevel to prevent a sharp edge.

Due to a chemical reaction that occurs between acrylic and isopropyl alcohol, We had banned the use of isopropyl alcohol during final assembly.

- Demo Lens

The Demo Lens is a white PC Material, and the lens is a part of the spherical surface. Demo Lens come in different curvatures and thicknesses, and lens sizes come in a variety of specifications.

The curvature of the lens is expressed by the mirror curve. The commonly used lens curvature is 400~600 for the optical frame and 600~800 for the sun frame.

The specifications of the Sun Lens are expressed by the size, thickness and mirror curvature of the lens, such as: medium 70×1.8×600. The common thickness specifications of the solar lens are: 1.5 , 1.8 , 2.0 , 2.3 , 2.5 , 3.0 mm

- Ordinary sun lens

Ordinary sun lens mainly include AC sheets (polymethyl methacrylate) and PC sheets (polycarbonate). AC lens is a hard resin lens, the most commonly used is CR-39 lens (Colombia Resin Columbia Resin 39).

- Polaroid Lens

Polaroid lens is a kind of polarizing lens (also known as polarizing lens), which has the advantages of lighter specific gravity, better strength and hardness, wear resistance, high temperature resistance, better toughness, and 100% blocking of ultraviolet rays than ordinary resin lenses, is an ideal lens for making sun frames.Polaroid chips are generally square, and their specifications are the size of the lens. Thickness and mirror bend are expressed, such as: 5 5 × 5 5 × 0.7 5 × 6 0 0 . Common thickness specifications of Polaroid slices are: 0.75 , 0.9 , 1.1 , 1.3 ,1.5 , 1.8 mm.

Now, do you already know what parts are available for eyeglass frames? What are their names? I believe that upon reading the anatomical diagram of the parts and the above description, you have already recognized different parts and their different functions.

Accordingly, a complete pair of glasses, in the production process, everyone sees a different shape, simple and clear, and more about the design of the combination of parts. Only through the perfect combination of parts can consumers purchase unique and comfortable glasses.