As the demand for personalized custom eyeglass frames continues to grow, custom-made eyeglass frames are becoming the current trend. However, customizing glasses by hand is not a new thing. The previous sunglasses manufacturers did not have the conditions for mass production, and customizing by hand was the only way to match glasses.

1. The process of handmade custom eyeglasses frames

In modern times, the technology of optometry and lens polishing has gradually matured, and the tools for making glasses have become relatively unified. The process of custom-made eyeglass frames has also become more and more mature, which mainly includes the following steps:

(1). Early communication for custom eyeglass frames

The eyewear designer will fully communicate with the customer, assess their needs, and provide multiple basic designing sunglasses options to choose from;

(2). Measure size and data for customized eyeglass frames

Measure eye data such as myopia, hyperopia, and astigmatism, as well as head size, nose bridge height, cheekbone height, nose bridge width, etc. to determine the size of the frame and temples.

(3). Personalized refinement for custom eyeglass frames

After the approximate size is determined, in order to optimize the wearing comfort, based on the customer’s personalized problems, such as glasses clip, slippage, and deflection, the body data is carefully measured again, the sample is repeatedly tried on, and the drawings are modified.

(4). Choose glasses material and glasses parts

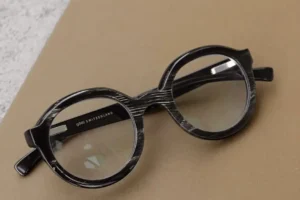

Precious metals, ivory, horns, cowhide, wood, tortoiseshell, gemstones, etc. are all optional materials for glasses. Some high-end glass shops with special craftsmanship also provide engraving and nameplate services.

(5). sample for custom eyeglasses frames

After all the parameters are determined, a first version is made with basic materials and fitted with lenses to become suitable trial lenses. Final modification opinions will be formed after trial trials and feedback.

(6). Handmade processing for custom-made eyeglasses frames

Use selected materials to create the final product.

It can be seen that in the past, the customization cycle of glasses was long, and the relationship between the optician and the customer was far beyond the normal relationship between buyers and sellers. In addition to the material and labor costs, the high customer price also included this strong personal service attribute. However, with the advancement of technology, custom sunglasses manufacturers have shortened the time to make a custom.

2. Handmade custom glasses gradually becoming popular

With the advancement of material technology and processing technology, custom glasses are turning to lightweight and durable materials, paying more attention to the wearer’s comfort needs and compensating for physical defects, with the main pursuit of providing customized vision correction. And provide the right amount of styles, colors, and sizes to choose from.

In addition, the current demand for creating your own sunglasses is also growing.

At the same time, the SKU of customized glasses has been greatly enriched. Some brands have launched special styles such as Asian models, European models, large and small sizes, etc. It only takes a little time to combine different specifications with the help of an optician consultant/salesperson. This semi-customization of standard parts is called “customization.”

The selling points of today’s handmade custom glasses are tailor-made, unique shapes and sizes, rich material combinations, and the psychological value of pure hand processing.

3. Handcrafted custom glasses of the future

The customizable nature of eyewear comes from its precise fit and decorative properties for correcting vision. Hand-made glasses from ancient times to the present are also developed around these two points: tailor-made, precise manufacturing, to provide the wearer with the most face-fitting and most comfortable wearing experience; independent choice of shape and material brings identity, Highlighting the spiritual value of personality.

Just imagine, if you pursue the ultimate precise fit, the most accurate vision correction, and wearing comfort, what kind of customized glasses will you get? Today’s technology gives us the opportunity to enjoy the ultimate fitting and unique wearing experience with the help of facial scanning technology, computer-aided modeling technology, and 3D printing technology – 3D printing glasses.

At the same time, it is recommended that everyone learn the technology of hand-made glasses from the famous Marchon glasses manufacturer.