The eyeglass frame salt spray test is a widely used method to assess the corrosion resistance and durability of various materials, including eyeglass frames. Eyeglass frames are exposed to various environmental conditions, including sweat, humidity, and exposure to saltwater.

Conducting a 48-hour salt spray test helps determine the frame’s ability to withstand these corrosive elements. In this article, we as sunglasses manufacturers will delve into the details of the 48-hour salt spray test for eyeglass frames and its significance in ensuring their quality and longevity.

1. Purpose of the Salt Spray Test

The primary purpose of the salt spray test is to simulate and accelerate the effects of corrosion on eyeglass frames.

Ensure that the eyeglass frames have sufficient corrosion resistance to prevent issues like peeling or tarnishing caused by sweat, which could potentially harm the wearer’s health and safety.

Ensure that the metal components of the eyeglass frames have a reliable level of plating or coating that provides effective corrosion protection.

2. Testing Procedure of the Salt Spray Test

(1)Prepare 2-4 samples and bend the ends of the samples at a 30-degree angle to check for corrosion resistance.

(2)Prepare the saltwater solution: Mix 50±5 grams of table salt and 0.25±0.02 grams of cupric chloride dihydrate per liter of water. Adjust the solution’s pH to be between 3.1 and 3.2 using vinegar. Pour enough solution into the spray machine’s storage chamber.

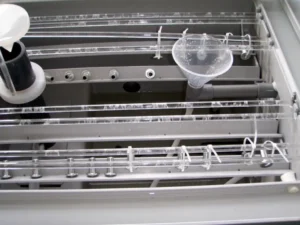

(3)Adjust the spray nozzles to ensure that the test area in the spray chamber collects 1.0-2.0 milliliters of the solution per hour for every 80 square centimeters.

(4)Close the spray machine’s lid and turn it on, allowing the temperature inside to reach 50±2 degrees Celsius.

(5)Place the samples with the surface facing up inside the spray chamber, making sure they don’t touch other samples or the chamber walls. Ensure no water droplets from upper samples fall onto lower sample surfaces.

(6)Maintain continuous salt spray for 24 hours.

(7)Open the flushing valve to remove the salt spray from the chamber. Turn off the spray machine, take out the samples, and let them air dry naturally for 0.5-1 hour at room temperature to prevent corrosion byproducts from escaping. During the final inspection, lightly rinse the samples with flowing water, then use a hairdryer from a distance of 30 cm to dry them.

(8)Examine the samples’ surfaces for corrosion and make appropriate records.

3. Evaluation Standards of the Test

After the 48-hour test time, the eyeglass frames are inspected for any signs of corrosion, discoloration, or damage. The evaluation standards include:

(1) Corrosion Resistance: The eyeglass frames should exhibit minimal or no signs of corrosion, such as rust or pitting, indicating their ability to resist the corrosive effects of saltwater.

(2)Colorfastness: The eyeglass frames’ surface finish, including any coatings or paint, should remain intact without fading or discoloration.

(3)Structural Integrity: The frames should maintain their structural integrity, with no signs of warping, bending, or weakening due to exposure to saltwater.

(4)Functionality: Hinges, temple, and other moving parts should continue to operate smoothly without any degradation in performance.

4. Significance of the Eyeglass Frame Test

The salt spray test is the most important quality control measure for eyeglass frames. It ensures that eyeglass frames can withstand the harsh conditions they may encounter during daily wear, such as exposure to perspiration, humidity, and occasional contact with saltwater.

Frames that pass the salt spray test demonstrate their ability to maintain their appearance, functionality, and structural integrity over an extended period.

Conclusion:

The 48-hour salt spray test is a vital evaluation method for assessing the corrosion resistance and durability of eyeglass frames. By subjecting frames to a simulated saltwater environment, custom sunglasses manufacturers can ensure that their products meet stringent quality standards and offer long-lasting performance.

Consumers can have confidence in choosing eyeglass frames that have successfully undergone this rigorous test, knowing that they are well-equipped to withstand the demands of everyday use and maintain their quality over time.