In 2023, the sunglasses manufacturing industry witnessed increased competition in certain areas. However, this had minimal impact on sunglasses manufacturers who adhere to production and control standards. I believe the main reasons for this lie in longstanding issues: quality, delivery time, and pricing.

Companies that prioritize maintaining high quality, meeting quantity demands, delivering on time, and setting reasonable prices are less affected by seasonal fluctuations in orders. This will continue to be a critical factor in the competition among custom sunglasses manufacturers in the future.

1. Sunglasses manufacturing is either dealing with balanced quantities or rushing the delivery time

At present, what is the current situation of our glasses factory? Many factories are either dealing with tail numbers or rushing to deliver. The main factors causing these problems are as follows:

1. Personnel issues: High employee mobility leads to inconsistency in stable quality. There is no training on the job, and the job is started when the technical standards are not up to standard.

2. Equipment performance: The quality of the equipment is substandard and the output products are unstable.

3. Supporting problems: There are many manufacturing processes for glasses and many supporting factories, resulting in serious problems such as the unqualified quality of incoming materials, delays in outsourced processing, and odd numbers.

4. Management issues: Many factories have no standardized management and do not pay attention to regulations. There is a situation where the busier they are, the more chaotic they become. Through standardized management, the first three problems can be effectively optimized.

In my 24 years of glasses-related work, I have attached great importance to standardized operations. I have been doing departmental standardized production in a large glasses company in Shenzhen. The above are just a few points from the perspective of the role of standardized operations in management.

2. Share a case in eyewear manufacturing management

Standardization is easier said than done. The most important thing is persistence. Let me share a case first. From 2003 to 2007, I worked in the production management of the manufacturing department of a large glasses company. One thing the glasses production department did was to establish standards, implement standards, revise standards, and then implement standards.

The cycle continues throughout the year. From adjusting one model in one day in the beginning, any apprentice can basically adjust one model in an hour after studying for a month in the later stage, and the quality and production speed have also been qualitatively improved. The quality and adjustment speed at that time were also superior. Manufacturers of high-end sunglasses manufacturer set several standards:

1. Standardization of drawings: Instead of producing according to sample racks, drawings are the only standard for quality inspection.

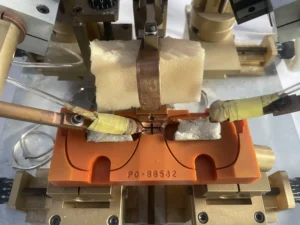

2. Standardization of tooling and fixtures: Standard drawing and production are done in any process from tooling to ensure stability and greatly reduce the time for adjustment.

3. Programming standardization: Standardize the programming tool, standard layer use, tool path specification, tool path specification, speed, tool speed, and other specifications.

4. Equipment standardization: Adjust the tool placement, tool installation length, processing coordinates, and the corresponding center point of the fourth axis of the rotation axis of all equipment to be the same, adjust the machine tools with tolerances, and transfer any program to any machine The equipment results are the same.

5. Standardization of work processes: programmers are professional in programming, machine adjusters are professional in machine adjustment, supporting personnel are professional in supporting, etc. After more than a year of optimization, quality problems often occurred while working overtime every day. Later, production tasks were easily handled, and quality was improved. Continued steady improvement.

3. Eyewear manufacturing from creating standards to constantly challenging standards

Every high-quality sunglasses manufacturer has its characteristics, and how to establish standards, and where to start will be different. The same standard, the above-mentioned method is not suitable for small factories. How to establish a sunglasses manufacturing standard that suits them needs to be set by each enterprise according to the actual situation, but the establishment path and ideas will be roughly the same.

1. Training. The main body of the standardization operation center is people, especially management personnel. People’s thinking is not unified, and they do not recognize standardization. Enterprises cannot do standardization well. This can be done by using means such as 5-minute morning meetings to continuously train long-term standardized operations on the role of enterprises in their literacy.

2. Start simple. Standardized work is long-term work, and the results cannot be seen in one or two days. Therefore, we must start with simple standards that can see the results relatively quickly, build employee confidence, use examples for training, and speak with facts.

3. To strictly follow the standards. The sunglasses manufacturing standards set must be strictly enforced without conditions.

4. Constantly challenge the standards. The challenge here is to allow others to make suggestions to improve the standard, conduct test experiments according to the suggestion, and raise the standard. The person or department who sets the standard needs to constantly try to improve the process and raise the standard.

5. Lower your posture. Although as an enterprise’s sunglasses manufacturing standard, it only means that the effect within the enterprise is relatively good, science and technology are constantly advancing, and the standards we consider are sometimes the standards that others have eliminated. Therefore, we must continue to learn, continue to accept new things, and constantly raise standards.

6. Be good at using external help. Be good at using tools, such as automation equipment, software tools, and industrial robots; It may be difficult for you to establish a standard, but an industrial robot or automation equipment can easily replace it; it may be difficult for you to control the eyeglass production process, and software tools can easily help you accomplish.

In the future, there are variables as to whether the sunglasses market will get better or worse. High-quality sunglasses manufacturers need to constantly improve and improve. We cannot always think that others will take an order of $8 and we will take an order of $7.8. By improving and upgrading the sunglasses manufacturing capabilities, let customers think that for $16 you can also make glasses. Even further, the quality of $50 requires you to do the same well.

At the same time, it is more like a large international glasses manufacturer learning glasses manufacturing, such as Marchon.