Choosing the right eyeglass frames is important, but choosing the right lenses is also critical. Have you fully informed yourself about the different types of glasses lenses for your health? So what are the common eyeglass lens materials, and which ones are better?

In daily life, many people often wear glasses, but have little understanding of how to differentiate and choose right lenses for themselves. Today, we sunglasses manufacturers will categorize the most important part of glasses – the “lenses” – into common materials and compare their pros and cons. Doing this will help you easily select the right, comfortable lenses when ordering glasses in the future.

1. Types Of Lens Materials

(1) Resin Lenses

Resin lenses are one of the most commonly used lens materials today. Resin is a polymer compound that softens when heated and people can mold it. Manufacturers make resin lenses by chemically synthesizing resin material and processing it into lens form through grinding and polishing.

Advantages of Resin Lenses:

Resin lenses have clear advantages. Lenses made from resin are lightweight so wearing them is more comfortable. Resin lenses also have strong impact resistance so they are not easy to break which is safer. Additionally, resin lenses have good light transmittance and are easy to reprocess to meet special needs, they are inexpensive, so they have become the mainstream lens material on the market.

Disadvantages of Resin Lenses:

Resin lenses have worse scratch resistance and chemical corrosion resistance on the surface compared to glass, and their surface is easy to scratch. Resin also has higher water absorption than glass. Manufacturers can improve these disadvantages through coating methods. The fatal flaw is resin has a high thermal expansion coefficient, poor heat conduction, and low softening temperature, which can easily lead to deformation and impact optical performance.

(2)CR39 Lenses

CR39 is an abbreviation for allyl diglycol carbonate, also known as Columbia resin or ADC resin. It is a thermoset material and the most widely used resin for producing regular plastic lenses.

Advantages of CR39 lenses:

CR39 also has the advantages of being easy to tint, impact resistant, and chemically stable. It was developed by PPG in the United States in the 1970s, and rapidly gained popularity. China started producing CR39 lenses in the 1980s. Lenses made of this material are best suited for vision correction for middle school and elementary students, children, as well as safety goggles and reading glasses. But for stronger prescriptions, high refractive index resins may be used instead due to thinner lenses.

Disadvantages of CR39 lenses:

CR39 is not as scratch resistant as glass and needs anti-scratch coatings. Resin lenses can be pattern pressed to create the curvature, making them well-suited for production of aspheric lenses.

(3)Glass Lenses

Advantages of Glass Lenses:

Glass lenses are lenses made from optical glass. They have slightly higher clarity than resin lenses, and also have relatively high refractive indexes. The highest refractive index used for lenses is 1.9. In addition, the glass lens surface is very hard, making glass lenses more scratch and wear resistant than lenses of other materials.

Disadvantages of Glass Lenses:

Due to the material, glass lenses are quite heavy, which affects comfort to some degree when wearing them. Plus glass itself is prone to shattering, especially as resin lens production technology and techniques have improved over the years, glass lenses have become less and less common recently.

(4)Polycarbonate Lenses

Advantages of Polycarbonate Lenses:

Polycarbonate lenses are also called “space lenses”. Their chemical name is polycarbonate (a thermoplastic material). Polycarbonate lenses are tough and shatter-resistant, which can effectively prevent lens breakage during intense sports. So they are also called safety lenses. At the same time, PC lenses are lightweight and have good UV protection. Therefore, PC lenses are mainly used in sunglasses and sports glasses.

Disadvantages of Polycarbonate Lenses:

The surface of PC lenses is easily scratched, and they are expensive, difficult to process, and have less than ideal dispersion control. Therefore, PC lenses only have a small share of the consumer market.

(5)Nylon Lenses

Nylon lenses mainly use the material TROGAMID CX – special transparent polyamide (commonly known as memory nylon), and are mostly used in sports brand sunglasses and high-quality sunglasses.

Advantages of Nylon Lenses:

Nylon lenses have high elasticity and excellent optical quality. They have extremely strong impact resistance, are very lightweight, about one-tenth the weight of the same volume of glass, and only half the weight of traditional resin lenses. As a thermosetting material, nylon can be recycled and processed into other industrial products, giving it renewability.

Disadvantages of Nylon Lenses:

Nylon lenses have poor scratch resistance. The lens surface needs a hard anti-scratch protective film for better durability in use. The lenses also have relatively poor workability, requiring professional processing equipment and technicians.

(6)AC Lenses

Both PC and AC lenses are resin lenses, they just have different manufacturing processes. The difference is that PC lenses are harder while AC lenses are softer. AC lenses are also called acrylic lenses. They have excellent toughness, are lightweight, have very high light transmittance, and good anti-fog properties.

Disadvantages of AC Lenses:

As a type of resin lens, AC lenses share the disadvantages of high thermal expansion coefficient, poor thermal conductivity, and low softening temperature, which can easily lead to deformation and negatively impact optical performance.

(7)Polarized Lenses

Polarized lenses are made by laminating multiple layers of resin lenses, which can filter out interfering irregular light rays to prevent glare and eye strain. They are globally recognized as the most suitable lenses for driving, and are commonly used in sunglasses. Polarized sunglasses are a must-have item for drivers and fishing enthusiasts.

Disadvantages of Polarized Lenses:

If the curvature of the lenses themselves does not meet the optical standards for refractive state, the polarizing effect will be weakened, affecting image authenticity. Polarized lenses also have poor durability.

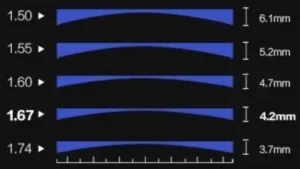

2. Types of Lens Refractive Index

The lens refractive index refers to the numbers 1.49, 1.56, 1.60, 1.67, 1.71, 1.74 etc marked on lenses. It indicates the refractive index of the lens material. For nearsighted prescription glasses, given the same other parameters, the higher the lens refractive index, the thinner the edge thickness and lighter the lens.

Currently, the mainstream lens refractive indexes on the market are: 1.56 , 1.60 , 1.67 , 1.71 , 1.74 and a few others.

For nearsighted people, lenses with refractive indexes of 1.67 and above are recommended, as they are thinner and lighter. The higher the refractive index, the thinner the lenses. However, high index lenses above 1.74 can sometimes cause aberrations and distortions. Discuss your needs with your optometrist to choose the right refractive index for your prescription glasses lenses.

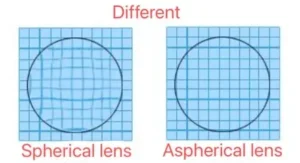

3. Difference Between Spherical and Aspheric Lenses

Spherical Lenses: The physical shape of spherical lenses cannot focus light perfectly, leading to increased aberrations and distortions. This results in obvious unclear vision, image distortion, and narrowed visual field.

Aspheric Lenses: The aspheric design corrects image issues and solves problems like image distortion, while also making the lenses lighter, thinner, and flatter. Aspheric lenses also maintain excellent impact resistance.

The aspheric surface profile better controls how light travels through the lens, reducing aberrations for sharper vision. Aspheric lenses provide a wider, undistorted field of view. The optimized optics and thin profile make aspheric lenses ideal for strong prescriptions and fussy wearers. Discuss your vision needs with your optometrist to determine if you will benefit from aspheric lenses.

(1) Advantages of Aspheric Lenses:

- Sharper vision: Aspheric lenses with special proprietary coatings provide superior optics for clear, comfortable viewing.

- Greater comfort: Aspheric lenses are so lightweight you barely notice them. They slim down the lenses to give your eyes a feather-light feel.

- More natural vision: The aspheric design provides more natural sight with less distortion for truer viewing.

Aspheric lenses also offer a wider undistorted field of view compared to traditional spherical lenses. The optimized optics and thin profile make aspheric lenses ideal for strong prescriptions. Discuss your vision needs with your optometrist to determine if you will benefit from lighter, thinner aspheric lenses.

4. Important Quality Testing Parameters for Lenses

(1)The refractive index of prescription eyeglass lenses

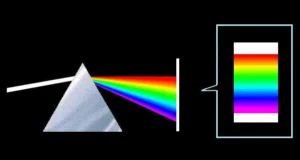

The refractive index is the ratio of the sine of the angle of transmitted light to the sine of the angle of incident light through the lens. Its value is generally between 1.49-1.74. For the same prescription, the higher the refractive index, the thinner the lens. However, the higher the refractive index of the material, the worse the chromatic dispersion.

(2)Scratch Resistance of Lenses

Scratch resistance refers to the degree of damage to the light transmittance of the lens surface under external force. Lens scratches are an important factor affecting lens lifetime and visual performance. In China, haze value (Hs) is commonly used as an indicator, with values generally between 0.2-4.5, the lower the better. The BAYER method is commonly used overseas, with values between 0.8-4, the higher the better. Hard resin lenses referred to generally have better scratch resistance than regular resin lenses.

(3)UV Cutoff Rate

Also called UV value, the UV cutoff rate is an important indicator for evaluating a lens’ ability to effectively block UV radiation. The value must be greater than 315nm, and is generally above 350nm and below 400nm. The UV400 lenses commonly mentioned in optical shops can effectively block UV radiation. Manufacturers can also add anti-radiation coatings to resin lenses.

UV protection is critical as exposure can cause eye conditions like photokeratitis, pterygium, and cortical cataracts. Quality prescription lenses filter out 99-100% of UVA and UVB rays to protect vision and eye health. Discuss your lens options with your optometrist to ensure you get lenses with sufficient UV blocking for your needs.

(4)Light Transmittance of Lenses

Light transmittance of lenses refers to the ratio of transmitted light to incident light through the lens. The higher the light transmittance, the clearer the lens. High quality eyeglass lenses are engineered for maximum clarity and light transmittance for sharp, undistorted vision.

Advanced lens coatings like anti-reflective further enhance light transmission. Discuss your vision needs with your optometrist to select lenses with optimal light transmittance for your prescription eyeglasses.

(5)Abbe Number of Lenses

The Abbe number is an inverse proportional index used to indicate the dispersion ability of transparent substances. It can be used to reference a lens’ ability to resolve interference and color discrimination of visible light. Values range from 32-60. The higher the Abbe number of the lens, the less distortion.

(6)The impact resistance of the lens

The impact resistance of a lens refers to its mechanical strength to withstand impact. Resin lenses have stronger impact resistance than glass lenses, and some resin lenses can even withstand blows without breaking.

(7)The firmness of the coating layer of the lens

This criterion is used to reference the lifespan of the coating layer on coated lenses. Many consumers will request coated lenses, and there are various types of coatings with different functions. Some lenses even have multiple coatings. Common coatings include anti-reflective coating, hard coating (anti-scratch coating), and anti-radiation coating.

If regular lenses provide clear vision, coating is not necessary. However, if coating is desired, resin lenses can be coated with anti-reflective or hard coatings, while glass lenses usually only receive anti-reflective coating.

(7.1)Anti-reflective coating of the lens:

Utilizing the principle of optical interference to reduce unnecessary reflection on the surface of the lens, increase transmittance, reduce glare, and improve clarity. It also enhances the appearance of the lens by reducing reflection.

(7.2)Hard coating of the lens:

Effectively protects the lens surface from wear and tear, and can resist damage from hard objects, thus prolonging the lifespan of the lens. It is generally applied to the front surface of the lens, enhancing the scratch resistance of resin lenses and increasing the transparency of light.

(7.3)Anti-radiation coating of the lens:

Blocks harmful ultraviolet radiation in sunlight, making it recommended to wear glasses that absorb 99-100% of ultraviolet radiation.

(7.4)Anti-fouling coating of the lens:

Due to the large gaps between molecules in the reflective coating, dirt and debris can easily accumulate on the lens surface. The small particle size and small gaps between molecules in anti-fouling coating make the lens surface smoother, providing additional functions such as water resistance, anti-fog, and anti-dust.

(7.5)Anti-radiation performance of the lens:

Refers to the ability of the lens to shield electromagnetic radiation by vapor-depositing a certain conductive material. Anti-radiation lenses have become the mainstream of coated lenses.

(7.6) Specific gravity of the lens:

Indicates the density of the material. The smaller the specific gravity of the material, the lighter the lens can be manufactured. Nowadays, lightweight lenses are increasingly favored by customers.

(7.7)Polarization lens:

Polarized lenses can protect people from the harm of reflected light, enhance outdoor visual contrast, and reduce glare, especially while driving. Polarized lenses are commonly used in most tinted sunglasses.

(7.8)Other physical indicators:

Flame retardance, yellow index, dent resistance, color change, etc.

In conclusion, there are many types of eyeglass lenses to choose from, each with its own unique features and benefits. Some of the most common types include single vision lenses, bifocal lenses, progressive lenses, and coated lenses. When choosing the right lenses for your needs, it is important to consider factors such as your prescription, lifestyle and budget. Consulting an optometrist or eyewear specialist can also help make an informed decision.

Here, custom sunglasses manufacturers feel your reading, and you are welcome to leave valuable suggestions.